The unique aromas of bourbon are influenced by a variety of factors, from the grains used to the ageing process in charred oak barrels. The primary components of its scent include sweet, vanilla, and caramel notes from the corn base and charred wood, with hints of spice and oak. The type of grains used, such as corn, rye, wheat, and barley, contribute distinct olfactory nuances, with corn lending sweetness, rye adding spice, wheat imparting softer, bread-like qualities, and barley providing nuttiness. The ageing process in charred oak barrels imparts additional complexity, with longer ageing resulting in mellower, more nuanced aromas. The interplay of these factors creates the distinctive and complex aroma profile of bourbon.

What You'll Learn

The role of grains

Corn, which is required to make up at least 51% of the mash bill, lends a mellow sweetness to the bourbon. It provides the foundation for the bourbon's overall flavour profile, with its sweet notes often described as reminiscent of vanilla, caramel, honey, maple, or butterscotch. The longer the bourbon ages, the more these sweet notes emerge and develop, creating a symphony of aromas that is synonymous with American whiskey tradition.

Rye, on the other hand, adds spice and fruity notes to the bourbon. It contributes to the spicy flavour profile with hints of cinnamon, cloves, and black pepper. The inclusion of rye in the mash bill can range from around 10% to 30%, and when a bourbon has more than 20% rye, it is often called a "High Rye Bourbon". Rye also imparts a dryer texture to the bourbon, balancing out the sweetness of the corn.

Wheat, which typically makes up a smaller percentage of the mash bill, contributes a softer, more mellow scent with slight bread-like qualities. It adds aromatic and fruity undertones, along with light honey flavour notes. A higher percentage of wheat in the mash bill can result in a creamier texture for the bourbon.

Malted barley, usually present in smaller quantities, provides a background of nuttiness and helps convert starches into fermentable sugars during the malting process. It develops subtle flavours such as light chocolate, nuts, and a hint of sourness.

The combination and ratio of these grains in the mash bill vary across different bourbons, influencing the distinct smell and flavour profile of each. The grains undergo fermentation and distillation, further enhancing and concentrating their aromatic and flavour characteristics. The choice of grains is a critical aspect of the bourbon-making process, requiring careful oversight by master distillers to achieve the desired balance of aromas and flavours.

Shiraz's Aromatic Profile: A Guide to Common Aromas

You may want to see also

The impact of yeast

Yeast is an essential component in the production of bourbon, and its impact on the final product is profound. Without yeast, there would be no alcohol in bourbon, but it also plays a crucial role in developing the spirit's unique flavours and aromas.

Yeast is a single-celled organism that feeds on the sugars present in the bourbon's mash, which is a mixture of grains and water. This process, known as yeast fermentation, converts sugars to alcohol and releases carbon dioxide. The carbon dioxide bubbles to the surface during fermentation, providing a visual indication of the yeast's activity.

The type of yeast used can have a significant impact on the flavour and aroma of the bourbon. While all bourbons use the yeast species Saccharomyces cerevisiae, this species has many different strains, and each strain produces distinct results. Some strains may favour the production of generic flavours like fruit, spice, floral, or herbal notes, while others might enhance specific grain flavours, such as rye or corn.

Yeast also produces aromatic compounds called esters, which are responsible for the characteristic scents of fruits and flowers. For example, the ester pentyl acetate gives bananas their distinctive smell, while methyl butyrate is responsible for the odour of apples. The specific yeast strain used will determine the types of esters produced, and slight genetic variations within the Saccharomyces cerevisiae species result in different esters being created. This is why changing the yeast strain changes the whiskey.

The fermentation process itself is complex and nuanced, and multiple factors influence the concentration and complexity of flavour compounds produced. These factors include the source of sugar, the temperature of the reaction, and the duration of fermentation. Additionally, the conditions used in the yeast fermentation process and the overall bourbon distillation process will also affect the final flavour of the bourbon.

Master Distillers carefully guard the secrets of their yeast strains, treating them as closely guarded secrets. They understand the crucial role that yeast plays in creating the unique flavour and aroma profiles of their bourbons.

Aroma Shipping: Why the High Costs?

You may want to see also

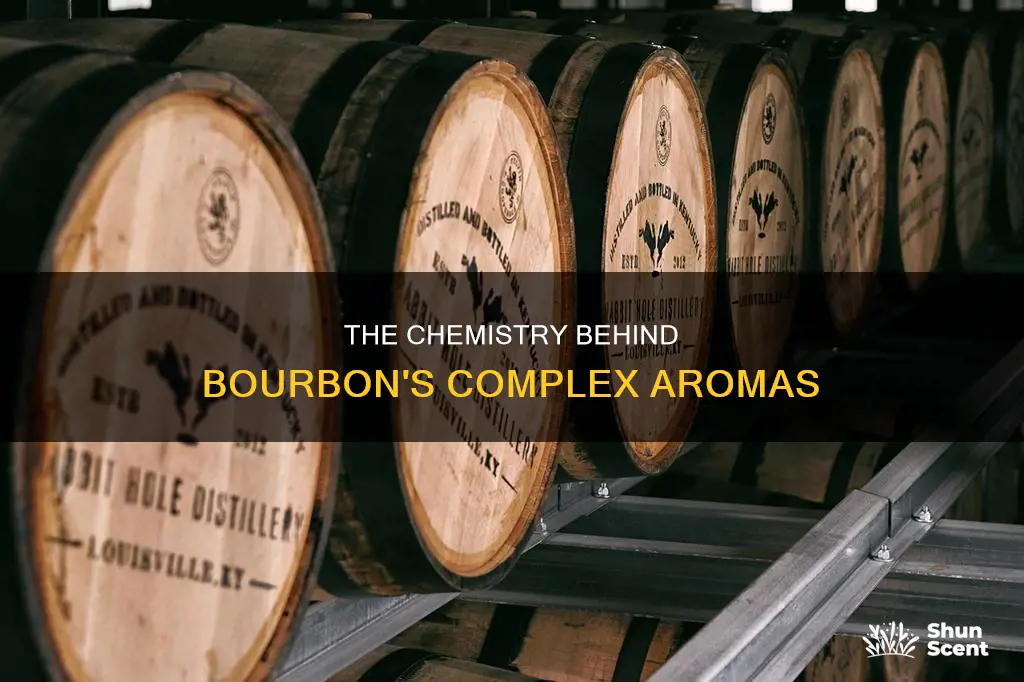

Barrel ageing

The oak barrels are typically charred on the inside, catalysing a series of chemical reactions that give bourbon its signature caramel and vanilla notes. The charring process also helps to evaporate any water and release sugars from the wood, giving the bourbon a warm and buttery character. The level of charring on the oak barrels will influence the smokiness of the bourbon, with more heavily charred barrels resulting in a smokier flavour.

The ageing process in the oak barrels also facilitates oxidation and the evaporation of less desirable compounds, further refining the bourbon's aroma. The duration of ageing significantly impacts the final product, with shorter ageing resulting in sharper, less mellow aromas, and longer ageing periods allowing for more nuanced scents to develop.

The oak barrels contain compounds such as tannins, vanillin, and lignin, which are absorbed by the bourbon during maturation, adding nuanced scents. Tannins lend subtle woody notes and can influence the dryness, while vanillin, derived from lignin, imparts a sweet, vanilla-like scent that becomes more pronounced over time. Lignin also introduces smoky and spicy tones to the bourbon.

The barrels used for ageing must be brand new and made from American oak, as mandated by bourbon production regulations. The oak provides lipids and cis or trans oak lactones, which contribute to the vanilla flavour. The oak can also add flavours similar to coconut and spices, with the spice derived from a macromolecule called lignin.

In summary, the barrel ageing process is fundamental to the development of bourbon's flavour and aroma, with the oak barrels and ageing duration playing pivotal roles in shaping the final product's unique sensory experience.

The Aroma Store: A Fragrant Experience

You may want to see also

The distillation process

Bourbon whiskey is distilled at no more than 160 proof (80% ABV) and then entered into the barrel for aging at no more than 125 proof (62.5% ABV). Techniques vary, with some distilleries using traditional pot stills while others use modern column stills, each imparting distinct qualities to the spirit.

The Evolution of Fragrant Flowers: Nature's Aromatic Wonder

You may want to see also

The influence of water

Water is an essential component in the creation of bourbon, influencing both its flavour and aroma. It is not just a simple ingredient but a key player that brings out the true flavours of the spirit. The type of water used in the distilling process can greatly impact the final product, from the source of the water to its chemical composition.

Mountain spring water, known for its purity and freshness, adds a delicate touch to bourbon, enhancing its smoothness and subtle flavours. The natural filtration process through layers of rocks and soil gives mountain spring water a distinct taste that adds complexity to the spirit. In contrast, river water, with its mineral-rich composition, can impart a distinct earthiness to bourbon, creating a smooth and velvety mouthfeel. Well water, sourced from deep underground, brings a unique combination of minerals that contribute to a more robust and complex flavour profile.

The mineral composition of water plays a significant role in shaping the taste and aroma of bourbon. Minerals such as calcium, magnesium, and potassium add depth and complexity to the spirit, while iron can introduce a subtle hint of earthiness. The right balance of minerals can elevate the bourbon's character. Additionally, the pH level of water affects the acidity and balance of the bourbon, with higher pH levels resulting in a smoother and more mellow flavour, and lower pH levels creating a sharper and more robust taste.

The choice of water source is crucial in unlocking the full flavour potential of bourbon. Each water source brings unique characteristics to the distilling process, and distillers may experiment with different sources to enhance the taste of their bourbon. The water's chemical composition, including its pH levels and mineral content, plays a vital role in shaping the taste profile of the final product.

The Chemistry of Scents: Volatile Aroma Compounds Explained

You may want to see also

Frequently asked questions

The primary aroma notes of bourbon are sweet vanilla and caramel, with hints of oak and spice.

Aging in charred oak barrels imparts woody and smoky fragrances to bourbon, with longer aging periods resulting in mellower, more complex aromas.

The grain bill, which includes corn, rye, wheat, and barley, contributes sweet, spicy, nutty, and bready notes to the aroma of bourbon.

Yeast adds nutty and fruity notes to the aroma of bourbon, with different yeast strains producing varying chemical compounds that form the background aromas.

Distillation acts on unwanted flavours and influences the mouthfeel of bourbon, resulting in a waxy or oily sensation.