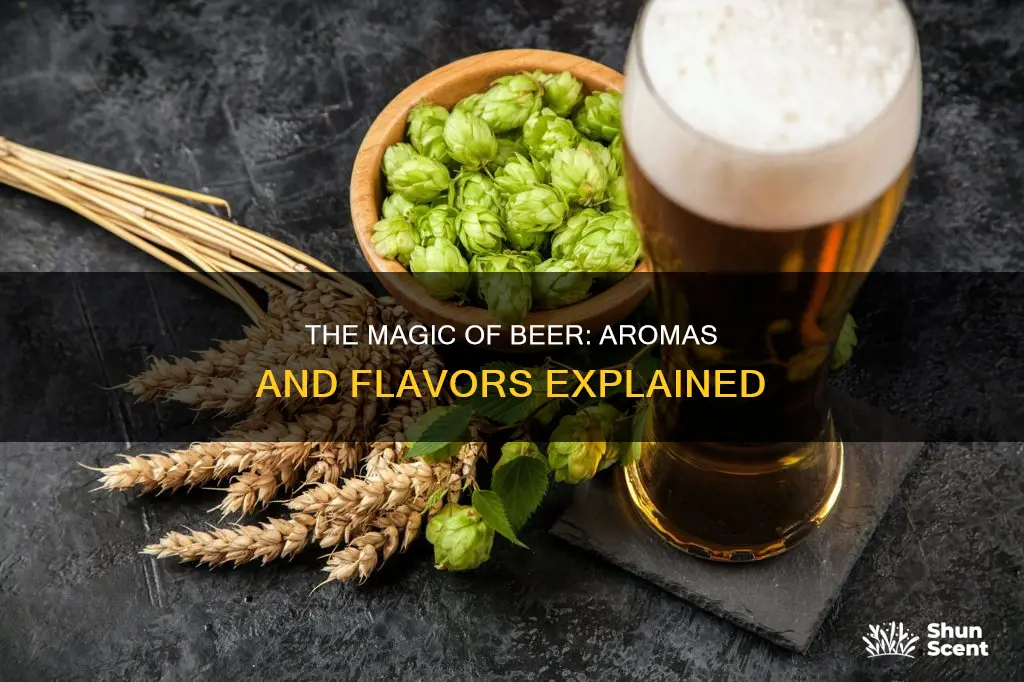

Beer is made up of hundreds of chemical compounds that contribute to its overall flavour and aroma. The specific types and amounts of these compounds depend on the raw materials used, the strain of yeast used, and how the important processing variables are managed during wort production, fermentation, and post-fermentation processing and packaging.

The aroma of beer originates from a number of sources, including the malt, hops, yeast, and any additional ingredients added during the brewing process.

Malt, which is made from barley, typically defines the beer's character. It can give off chocolate, coffee, and caramel notes, for example.

Hops, which are added during the boiling process, are responsible for the bulk of the aroma and flavour. Hops contain organic compounds called alpha and beta acids, which account for the bitter flavour. Hops also contain essential oils, which are very volatile and evaporate easily. These oils are responsible for the characteristic hoppy aroma of beer, as well as citrus or spice notes.

Yeast produces esters during the fermentation process, which give off a fruity flavour and scent.

In addition to these main sources of aroma and flavour, there are a number of other compounds that can play a part. For example, esters, which are present in varying degrees depending on the type of beer, are responsible for fruit-like flavours.

| Characteristics | Values |

|---|---|

| Aroma | Floral, fruity, citrus, grassy, spicy, caramel, woody, roasty, burnt, banana, apple, pear, pineapple, rose, lemon, orange, grapefruit, coconut, peach, apricot, strawberry, raspberry, blackcurrant, violet, piney, aniseed, nutty, maple-like, vanilla, sulfur, smoke, malt, hops, yeast, sulfur, sweet, green, earthy, musty, solvent-like, alcoholic, vinous, bitter, sour, stale, lightstruck, hoppy, tropical, citrusy, spicy, herbaceous, perfume-like, exotic, floral/sweet, citrus/terpenic, grassy/spicy/herbaceous, caramel/nutty, woody/smoky, roasty/burnt |

| Flavor | Sweet, sour, bitter, fruity, floral, citrus, aniseed, apple, banana, pineapple, pear, raspberry, rose, honey, coconut, peach, apricot, strawberry, blackcurrant, violet, piney, aniseed, nutty, maple-like, vanilla, sulfur, smoke, malt, hops, yeast, sulfur, sweet, green, earthy, musty, solvent-like, alcoholic, vinous, bitter, sour, stale, lightstruck, hoppy, tropical, citrusy, spicy, herbaceous, perfume-like, exotic, floral/sweet, citrus/terpenic, grassy/spicy/herbaceous, caramel/nutty, woody/smoky, roasty/burnt |

What You'll Learn

- Hops: Hops contain essential oils that are responsible for the bulk of the aroma and flavour of beer

- Yeast: Yeast produces esters during the fermentation process. These esters give off a fruity flavour and scent

- Malt: Malts range widely in taste and aroma, and they typically define the beer's character

- Carbonation: Carbonation can affect the volatility of flavour compounds, such as esters

- Water: Water is used to create the wort, a sugar-rich liquid, which is then strained and transferred to the brew kettle

Hops: Hops contain essential oils that are responsible for the bulk of the aroma and flavour of beer

Hops are the flowers of the hop plant (*Humulus lupulus*) and have been used in brewing beer for centuries. They are added at different stages of the brewing process to achieve different effects. Hops contain essential oils that are responsible for the bulk of the aroma and flavour of beer. The essential oils in hops are made up of a hydrocarbon fraction (containing only hydrogen and carbon) and an oxygenated fraction (containing hydrogen, carbon, and oxygen). The hydrocarbons typically make up 80-90% of the total oil content; the terpenes myrcene and β-pinene and the sesquiterpenes β-caryophyllene and α-humulene are the most prevalent constituents.

The specific combination of terpenes in a beer can vary depending on the hop variety, the timing of the hop addition, and the brewing technique. For example, dry hopping – the process of adding hops to the beer after fermentation – can enhance hop aroma without adding additional bitterness.

Hop oils are highly complex mixtures, with more than 500 compounds identified, and many remaining to be identified. The female flower of the hop plant has long been a friend to beer brewers around the world. Depending on the style of beer, hops can add balance to the finished product through bitterness, flavour, and aroma.

doTERRA AromaTouch: A Soothing Blend of Aromatic Scents

You may want to see also

Yeast: Yeast produces esters during the fermentation process. These esters give off a fruity flavour and scent

Yeast plays a significant role in the aroma and flavour of beer. Yeast produces esters during the fermentation process, which give off a fruity flavour and scent. Esters are responsible for a huge portion of yeast-derived beer flavour.

The most used yeast in craft brewing is Saccharomyces cerevisiae, which is used in the beer world to produce ales. Saccharomyces cerevisiae is known for yielding beers with easily discernable characters, most clearly in the form of esters, phenols, and alcohols.

Esters tend to come off as fruity in flavour, but each ester tastes a little different. For example, isoamyl acetate tastes like banana, while ethyl acetate tastes like nail polish remover. Ethyl caprylate and caproate taste like apples, pears, or anise.

Generally, ester production is directly related to fermentation, and warmer fermentation temperatures increase their presence. The strain of yeast being used also plays a large role in the presence of esters.

In addition to esters, yeast is also famous for producing CO2 and ethanol. While bubbles are great, it's the ethanol that gets most people going. Detectable at different thresholds, ethanol imparts a warming, drying, or astringent effect on the palate.

Exploring the Benefits of Orange Aromatherapy Oil

You may want to see also

Malt: Malts range widely in taste and aroma, and they typically define the beer's character

Malt is a key ingredient in beer and its flavour and aroma range widely. Malts are usually made from barley, but can also be made from wheat, rye, and oats. The malting process involves steeping the grains in water, allowing them to germinate, and then drying them in a kiln. This process creates the enzymes that will later convert starches into sugars and determine the flavour and colour of the beer.

The type of malt used in beer can have a significant impact on its flavour and aroma. For example, base malts, which are the most commonly used type of malt, provide the backbone of the beer's flavour and contribute a malty sweetness. On the other hand, speciality malts, such as crystal malts, can add flavours such as caramel, toffee, and nuts. Roasted malts, like chocolate malt and black malt, can add flavours like coffee, cocoa, and burnt grain.

The amount of time the malt is kilned also affects the flavour and aroma of the beer. Lighter kilned malts will contribute flavours like bread, biscuits, and honey, while darker kilned malts will contribute flavours like coffee, chocolate, and roasted barley.

In addition to the type of malt and kilning time, other factors such as the malt's origin, moisture content, and modification level can also impact the flavour and aroma of the beer.

Disney's Scented Secrets: Aromatic Pump Technology

You may want to see also

Carbonation: Carbonation can affect the volatility of flavour compounds, such as esters

Carbonation is an essential aspect of beer that greatly influences its sensory characteristics, including flavour and aroma. The carbonation process involves the dissolution of carbon dioxide (CO2) in the beer, which occurs naturally during fermentation or through forced carbonation methods. The presence of CO2 has a significant impact on the volatility of various flavour compounds, particularly esters, which are key contributors to the aroma and flavour profile of beer.

Esters are organic compounds formed during fermentation when alcohols combine with organic acids. They play a crucial role in imparting fruity, floral, or sweet aromas and flavours to beer. The type and concentration of esters varies depending on the yeast strain used during fermentation and the specific conditions maintained during the brewing process.

Carbonation affects the volatility of esters by altering the equilibrium between the dissolved CO2 and the ester compounds. When carbonation levels increase, the volatility of esters also tends to increase. This is because the dissolved CO2 molecules interact with the ester molecules, disrupting their molecular bonds and making them more energetically favourable to escape into the vapour phase.

The enhanced volatility of esters due to carbonation has a direct impact on the aroma and flavour perception of the beer. As esters become more volatile, they are more readily released from the liquid matrix into the headspace above the beer. This increases their concentration in the vapour phase, making it easier for our olfactory receptors to detect them when we take a sip or swirl the beer in our glass.

Additionally, carbonation can influence the perception of esters through the formation of carbonic acid. When CO2 dissolves in beer, it forms carbonic acid, which can affect the pH and acidity levels. These changes in the chemical environment can further impact the stability and perception of esters, as well as interact with other flavour compounds, creating a complex interplay of aromas and flavours.

Brewers can manipulate carbonation levels to accentuate or mellow specific ester characteristics in their beers. For example, a highly carbonated beer may emphasize the fruity notes contributed by esters, creating a more vibrant and effervescent sensory experience. On the other hand, a beer with lower carbonation might showcase subtler ester nuances, providing a smoother and more subdued flavour profile. Ultimately, carbonation serves as a tool for brewers to fine-tune their beers' characteristics and create distinct sensory journeys for beer enthusiasts to explore and enjoy.

The Significance of Aromatic Mass in Chemistry

You may want to see also

Water: Water is used to create the wort, a sugar-rich liquid, which is then strained and transferred to the brew kettle

Water is the primary ingredient in beer, making up about 90% of wort, the sugar-rich liquid that will eventually become beer. The first step in making wort is to obtain malt, which is made from dried, sprouted cereal grains, including barley. The malt is then milled, cracking the husk and exposing the starch inside. The milled grain is then mashed by mixing it with hot water, and then steeped, a process that enables enzymes to convert the starch in the malt into sugars which dissolve in the water. This mixture is called the mash.

The next step is lautering, where the sugar-extracted grist or solids remaining in the mash are separated from the liquid wort. The wort is then boiled or it will remain unstable. Boiling is a vital step because it sterilizes the liquid and halts the starch to sugar conversion. Hops are also added to the liquid wort during boiling to add bitterness and flavour.

Aromatherapy: Healing Power of Scents and Aromas

You may want to see also

Frequently asked questions

The aroma of beer comes from a combination of carbonation, hops, malt, water and yeast. The specific types and amounts of taste and aroma compounds within a particular beer depend upon the types and amounts of raw materials used in making the beer, the strain of yeast used to produce the beer, and how the important processing variables are managed during wort production, fermentation and post-fermentation processing and packaging.

The flavor of beer comes from the same sources as its aroma. The flavor of beer is also influenced by the chemical compounds that are responsible for producing the associated flavor perceptions.

Yeast and hops are the main sources of fruity and flowery aroma compounds in beer.

Broad flavor compound categories in beer include fruity/ester-like, floral/sweet, citrus/terpenic, grassy, spicy/herbaceous, caramel/nutty, woody/smoky, and roast/burnt.