Creating oil-soluble fragrance extracts from lychees is an intriguing process that involves transforming the natural aroma of this fruit into a stable, oil-based form. This method is particularly useful for creating perfumes, cosmetics, and other products that require a long-lasting scent. The process begins with carefully selecting ripe lychees, extracting their essence, and then utilizing various techniques to make the fragrance soluble in oils. This involves chemical processes such as esterification and solvent extraction, ensuring the final product retains the unique, sweet scent of lychees while being compatible with different oil-based formulations.

What You'll Learn

- Lychee Selection: Choose ripe, sweet lychees for optimal fragrance

- Extraction Method: Use solvent extraction or CO2 extraction for oil solubility

- Solvent Choice: Opt for a non-polar solvent like hexane for best results

- Temperature Control: Maintain low temperatures to preserve fragrance compounds

- Purification Techniques: Employ distillation or chromatography to isolate pure fragrance

Lychee Selection: Choose ripe, sweet lychees for optimal fragrance

When it comes to crafting oil-soluble fragrance extracts from lychees, the selection of ripe and sweet lychees is paramount. This process relies on the natural sweetness and aroma of the fruit, so choosing the right lychees is the first step to success.

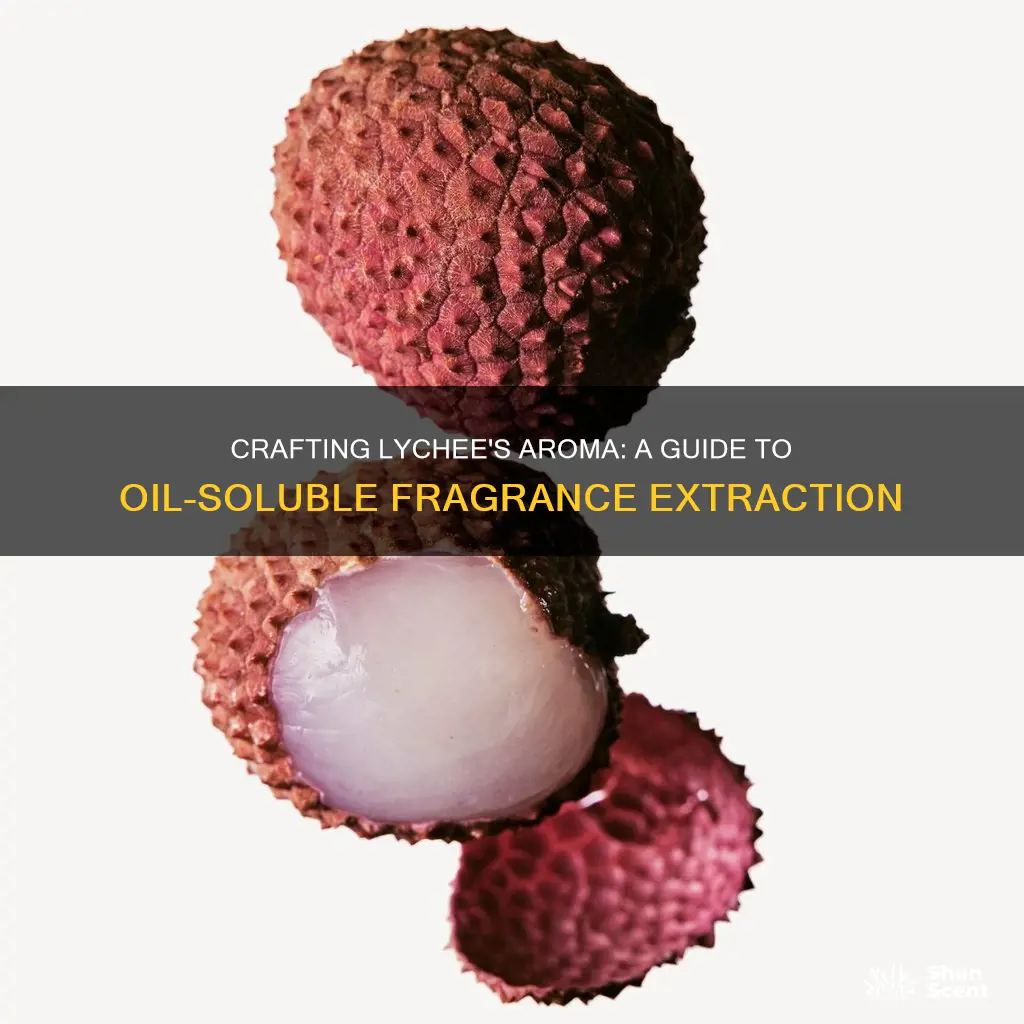

The ideal lychees for this extraction process are those that are fully ripe and sweet. Ripe lychees will have a vibrant, deep red color, indicating their maturity. A gentle squeeze should yield a slightly soft texture, but not mushy. The aroma should be sweet and enticing, with a hint of floral notes. Avoid any lychees that feel hard or have a green hue, as they may not be ripe enough to extract the desired fragrance.

Sweetness is another critical factor. The lychees should have a natural, sweet flavor that is not overpowering but rather delicate and pleasant. A simple taste test can help determine this; the fruit should melt in your mouth, leaving a lingering sweetness. If the lychees are not sweet enough, the fragrance extract may lack the desired appeal.

Additionally, look for lychees that are free from any signs of damage or mold. Inspect the fruit for any bruises or soft spots, as these can affect the quality of the extract. Fresh, undamaged lychees will ensure a pure and potent fragrance.

In summary, selecting ripe and sweet lychees is essential for creating a high-quality oil-soluble fragrance extract. The right choice of fruit will provide the necessary aroma and flavor, setting the foundation for a successful extraction process.

Unveiling Chanel's Scented Secrets: A Fragrance Collection Guide

You may want to see also

Extraction Method: Use solvent extraction or CO2 extraction for oil solubility

To create an oil-soluble fragrance extract from lychees, you can employ two primary extraction methods: solvent extraction and supercritical carbon dioxide (CO2) extraction. Both techniques offer unique advantages and can be tailored to suit your specific needs and resources.

Solvent Extraction:

This method involves using a solvent to dissolve the desired compounds from the lychees. Here's a step-by-step process:

- Preparation: Start by selecting an appropriate solvent, such as ethyl acetate or dichloromethane, which are commonly used for fragrance extraction due to their ability to dissolve aromatic compounds. Ensure the lychees are fresh and properly cleaned to avoid any unwanted flavors or odors.

- Extraction: Place the lychees in a suitable container and add the chosen solvent. Use a mechanical shaker or a soxher to agitate the mixture, allowing the solvent to penetrate the fruit and extract the fragrant compounds. The duration and intensity of agitation may vary depending on the desired concentration.

- Filtration and Concentration: After the extraction process, filter the mixture to separate the solid lychee material from the solvent-extracted fragrance. Use a fine mesh strainer or filter paper. Then, evaporate the solvent under reduced pressure using a rotary evaporator to obtain a concentrated fragrance extract.

- Purification (Optional): For a more refined product, you can perform additional purification steps like recrystallization or chromatography to isolate specific fragrance compounds.

Supercritical CO2 Extraction:

CO2 extraction is a more advanced technique that utilizes the unique properties of supercritical carbon dioxide.

- CO2 Preparation: Begin by supercritically extracting CO2 from the lychees. This is done by applying high pressure and temperature to CO2 gas, causing it to become a supercritical fluid with solvent-like properties.

- Extraction Process: Introduce the supercritical CO2 into the lychees, where it will dissolve and extract the fragrant compounds. The duration and pressure conditions will depend on the specific lychee variety and desired extract composition.

- Separation and Collection: After the extraction, the CO2 can be rapidly expanded to its gas phase, causing the extracted compounds to be released. Collect the resulting oil-soluble fragrance extract, which will be in a highly concentrated form due to the efficiency of CO2 extraction.

- Post-Processing: Similar to solvent extraction, you might want to perform additional purification steps to isolate specific fragrance components, ensuring a high-quality, pure extract.

Both methods offer effective ways to obtain oil-soluble fragrance extracts from lychees, each with its own advantages. Solvent extraction is more accessible and cost-effective, making it suitable for small-scale productions. In contrast, CO2 extraction provides a more environmentally friendly and efficient process, especially for larger-scale operations.

Creating a Unique Fragrance Line: Your Signature Scent

You may want to see also

Solvent Choice: Opt for a non-polar solvent like hexane for best results

When it comes to creating an oil-soluble fragrance extract from lychees, the choice of solvent is crucial. Non-polar solvents are ideal for this process, and hexane is a top choice for several reasons. Hexane is a non-polar, volatile, and non-toxic solvent, making it safe to use and easy to handle. Its non-polar nature allows it to effectively dissolve the fragrant compounds found in lychees, ensuring a high-quality extraction.

The process begins by finely chopping the lychees to increase the surface area, allowing for better extraction. The lychees are then soaked in hexane, creating a soapy mixture. This soaking process is essential as it enables the hexane to penetrate the fruit's cells and extract the desired fragrance compounds. The duration of soaking can vary, but typically, a few hours to overnight is sufficient to extract the maximum amount of fragrance.

After soaking, the mixture is filtered to separate the solid lychee material from the hexane-soluble extract. This step ensures that the extract is pure and free from any unwanted plant matter. The filtered extract is then ready for further processing or use. It's important to note that the extraction process should be done in a well-ventilated area due to the volatile nature of hexane.

Hexane's effectiveness lies in its ability to interact with the non-polar molecules of the fragrance compounds in lychees. Non-polar solvents are particularly good at dissolving similar non-polar substances. By using hexane, you ensure that the fragrance molecules remain intact and are effectively extracted, resulting in a potent and pure fragrance extract.

In summary, for the best results in creating an oil-soluble fragrance extract from lychees, opt for a non-polar solvent like hexane. Its non-toxic nature, volatility, and ability to dissolve non-polar compounds make it an excellent choice for this extraction process, ensuring a high-quality and pure fragrance product.

Macy's Men's Fragrance Sale: Best Deals and Offers

You may want to see also

Temperature Control: Maintain low temperatures to preserve fragrance compounds

Temperature control is a critical aspect of the process of creating oil-soluble fragrance extracts from lychees, as it directly impacts the stability and preservation of the delicate fragrance compounds. When working with natural ingredients like lychees, which contain volatile and heat-sensitive compounds, maintaining low temperatures is essential to ensure the best results.

The process begins with carefully selecting ripe lychees, as the fruit's natural ripeness contributes to the desired fragrance. After harvesting, the lychees should be immediately chilled to slow down the ripening process and preserve the integrity of the fragrance compounds. This initial step is crucial, as it sets the foundation for the entire extraction process.

During the extraction, low temperatures are maintained throughout to minimize the risk of degradation. Lychee fruits are typically processed using a solvent extraction method, where a suitable solvent, such as ethyl acetate or a mixture of alcohol and water, is used to extract the fragrant compounds. By keeping the temperature controlled, especially during the extraction and subsequent purification steps, the volatile fragrance molecules remain stable and intact.

It is important to note that high temperatures can cause the breakdown of these compounds, leading to a loss of fragrance and potential off-flavors. Therefore, a cold environment is necessary to preserve the natural aroma of lychees. Proper temperature control also ensures that the extracted fragrance remains oil-soluble, allowing for its effective use in various cosmetic, fragrance, or food applications.

In summary, temperature control is a key factor in the successful creation of oil-soluble lychee fragrance extract. By maintaining low temperatures, one can ensure the preservation of the desired fragrance compounds, resulting in a high-quality, aromatic product. This process requires careful attention to detail and a controlled environment to achieve the best outcomes.

Find the Perfect Scent: Discounted Perfumes to Buy Now

You may want to see also

Purification Techniques: Employ distillation or chromatography to isolate pure fragrance

The process of creating an oil-soluble fragrance extract from lychees involves a series of steps, and purification techniques are crucial to ensure the final product is pure and of high quality. Distillation and chromatography are effective methods to isolate the desired fragrance compounds from the lychee fruit.

Distillation is a widely used technique in the fragrance industry for purifying and concentrating natural extracts. It involves heating the lychee extract to a specific temperature, causing it to vaporize. The vapor is then cooled and condensed back into a liquid state, separating the fragrance compounds from other components. This process can be performed using various distillation methods, such as simple distillation or steam distillation. Simple distillation is ideal for separating volatile compounds, while steam distillation is gentle and suitable for heat-sensitive materials like lychee extracts. The collected distillate will contain the desired fragrance, which can be further refined through fractional distillation to obtain a more concentrated and pure product.

Chromatography is another powerful tool for purifying fragrances and is often used in conjunction with distillation. This technique relies on the differential distribution of compounds between a stationary phase and a mobile phase. In the context of lychee fragrance extraction, a suitable stationary phase could be an adsorbent material, such as silica gel, which interacts with the fragrance molecules. The lychee extract is applied to the stationary phase, and as the mobile phase (often a solvent) moves through the column, different compounds will be separated based on their affinity for the stationary phase. This results in a gradual elution of the fragrance compounds, allowing for their isolation and purification. Chromatography can be optimized by adjusting factors like solvent composition, column temperature, and flow rate to achieve the desired separation.

When employing these purification techniques, it is essential to consider the specific characteristics of the lychee fragrance. Lychees contain various volatile compounds, including esters, aldehydes, and terpenes, which contribute to the unique aroma. The choice of distillation or chromatography method should be guided by the compound's volatility, boiling point, and chemical properties. For instance, if the fragrance contains heat-sensitive components, steam distillation might be preferred to minimize degradation.

In summary, distillation and chromatography are valuable tools for purifying oil-soluble fragrance extracts from lychees. Distillation methods, such as simple and steam distillation, facilitate the separation of volatile compounds, while chromatography, utilizing adsorbent materials, enables the isolation of specific fragrance molecules. By carefully selecting and optimizing these techniques, one can obtain a pure and concentrated lychee fragrance extract, ready for various applications in the fragrance industry.

The Fragrant World of Tuberose: Unveiling Its Allure

You may want to see also

Frequently asked questions

The extraction process involves a series of steps. First, lychees are carefully selected and cleaned to ensure the highest quality. Then, the fruit is steamed or boiled to release the natural oils and fragrances. After that, the mixture is pressed to separate the oil from the solids. The oil is then refined through filtration and distillation to remove any impurities and to concentrate the fragrance.

Different extraction methods can significantly impact the quality and yield of the fragrance oil. For instance, steaming helps retain the natural aroma compounds, while boiling might extract more volatile compounds. The choice of method depends on the desired fragrance profile and the specific characteristics of the lychee fruit used.

While some basic steps can be performed at home, professional extraction is highly recommended for optimal results. Home extraction might lack precision and control over temperature and pressure, which are crucial factors in preserving the fragrance's integrity. Industrial-scale extraction also allows for larger quantities and consistent quality.

Lychee oil is sensitive to heat and light, so it's essential to work quickly and store the extracted oil properly. After extraction, the oil should be cooled and filtered to remove any remaining solids. It's also advisable to use dark glass bottles or amber containers to protect the oil from light exposure, which can cause oxidation and affect the fragrance's stability.