Aromatherapy oils are a great way to make your home smell nice, unwind after a long day, or even boost your mood. You can make your own aromatherapy oils at home using simple equipment and plants from your garden.

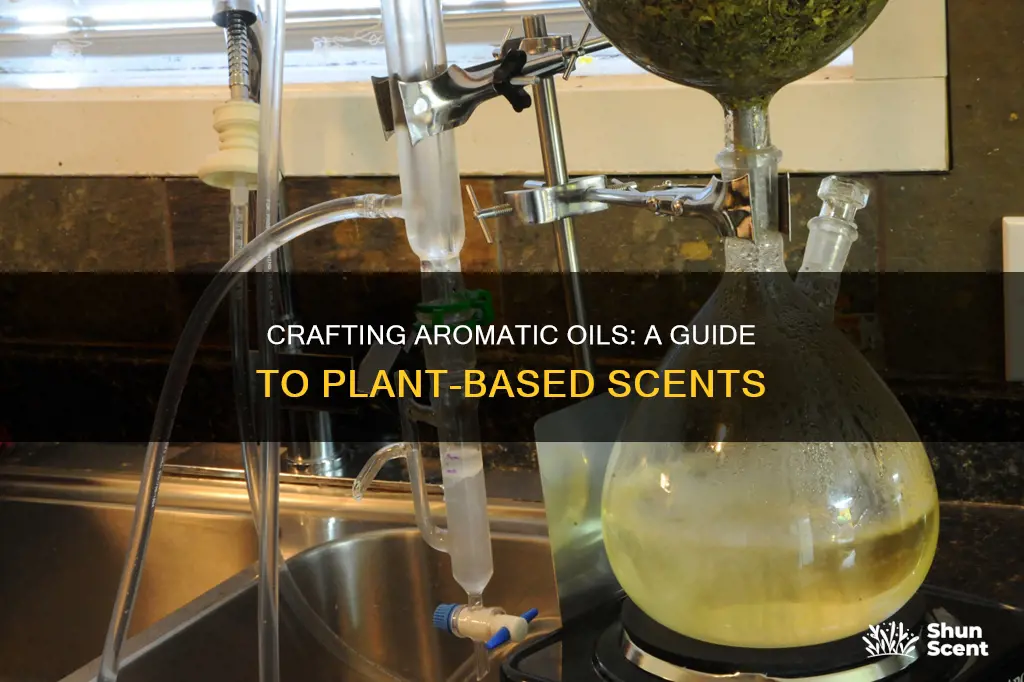

The most common way to make essential oils at home is through steam distillation. This involves boiling herbs and plants until the essential oils separate from the plant and float on the water. You can then collect the oil and store it in a glass bottle. However, this method does not result in pure, unadulterated essential oil, so the medicinal effects of the oil may be reduced.

Another method is to use a crockpot or stovetop. Place dried plant material in a crockpot or pot, cover with distilled water, and cook on low for 24-36 hours. After shutting off the heat, cover the crockpot or pot with a piece of cheesecloth and let it sit for a week. You can then collect any oils that have formed on the surface of the water and transfer them to a glass jar.

When making essential oils, it is important to use plants that have not been exposed to pesticides or other chemicals. It is also important to harvest the plants at the right time, typically just before flowering or when about half the flowers are open.

| Characteristics | Values |

|---|---|

| Methods | Extraction, distillation, expression, steam distillation, oil soak, cold-press method, crockpot, stovetop, enfleurage |

| Equipment | Crockpot, still, glass bottle or jar, carrier oil, wax paper, paper bag, cheesecloth, commercial press, filtering system, commercial still, glass container, reeds, bamboo skewers, porcelain-coated strainer, medicine dropper, freezer |

| Plants | Culinary herbs, lavender, rosemary, peppermint, lemon balm, calendula, citrus fruit rinds, rosemary, garlic, hot peppers, roses, carnations, frangipani, hyacinth, marigolds, cinnamon, coriander, cumin, nutmeg, cloves |

| Carrier Oils | Olive oil, grapeseed, coconut oil, jojoba oil, sweet almond oil, apricot kernel oil, avocado oil, fractionated coconut oil, sunflower oil, safflower oil, canola oil |

What You'll Learn

Steam distillation

Step 1: Prepare the Plant Material

Before starting the distillation process, ensure that you are using plants that have not been exposed to pesticides, herbicides, or chemical fertilizers, as these chemicals can contaminate the oil during steam distillation. Harvest your plants at the right time, which is typically just before flowering or when about half the flowers are open. Dry the plants in a warm but not hot area, away from direct sunlight, until they are no longer fragile but still feel dry.

Step 2: Set Up the Distillation Equipment

You will need a large container called a "still" made of non-reactive materials such as stainless steel. Place the plant material inside the still, adding enough water to cover the plants. The amount of plant material and water may vary depending on the size of your still.

Step 3: Apply Heat

Heat the still over a burner or heating element. The temperature should be carefully controlled and is typically set between 140–212 degrees Fahrenheit. This temperature range may vary depending on the type of plant material being used.

Step 4: Inject Steam

Through an inlet, inject steam into the plant material containing the desired oils. The steam will release the plant's aromatic molecules and turn them into vapour. Continue injecting steam until the plant material is fully vaporized.

Step 5: Condense the Vapour

Direct the vapour into a condensation flask or condenser. Here, the vapour will come into contact with cold water or another cooling agent, causing it to cool and condense back into a liquid state. This liquid will contain a mixture of water and essential oil.

Step 6: Separate the Oil and Water

The essential oil and water will naturally separate into two distinct layers due to their different densities. Carefully collect the essential oil, which will float on top of the water, using a siphon or dropper.

Step 7: Store the Essential Oil

Transfer the collected essential oil into an amber or blue glass bottle for storage. Essential oils are typically stored in dark-coloured glass bottles to prevent light from degrading the oil over time. Store the oil in a cool, dry place, and use it within 12 months for the best quality.

New Aroma Cards: Which Booster Packs to Buy?

You may want to see also

Solvent extraction

The process of solvent extraction can be further broken down into the following steps:

- The solvent is selected based on its affinity with the desired plant compounds.

- The solvent flows through the prepared plant biomass, breaking down plant structures and releasing the essential oils.

- The mixture of solvent, plant oils, and botanical solids is filtered.

- The filtered mixture undergoes vacuum distillation to remove the majority of the solvent, especially when using petroleum-based solvents.

- A small percentage of chemical solvent residue may remain in the final product.

Aroma's Vengeance: Effective Against Totem Armor?

You may want to see also

Maceration

The process of maceration involves leaving plant material in a carrier oil (e.g. sunflower or almond oil) for a period of time until the oil takes on the scent or qualities of the plant. The fat/oil naturally absorbs the fragrant molecules and other properties of the plant.

Step 1: Pick and chop up the raw plant material. This breaks the plant cells and releases the lipophilic molecules, including essential oil compounds. Drier raw plant material is better for this process.

Step 2: Put the chopped plant material into a base carrier oil, such as olive or sunflower oil, in an airtight container. Add 5% wheat germ to help preserve the oil.

Step 3: Store the container in a warm, sunny place, such as a windowsill, and stir frequently for up to three weeks. The sunshine will gently heat the oil and extract the plant's properties.

Step 4: After about three weeks, strain and filter the oil. Put the strained oil into a fresh jar and label it. The oil-soluble elements, colour, and essential oil compounds from the plant material are now in the carrier oil base, creating a ready-blended massage oil.

Macerated oils will generally last up to two years if kept airtight. These oils can be used like any other carrier oil, added to creams, used as bath oils, or applied topically.

Unraveling the Intricacies of Complex Aromas and Their Nuances

You may want to see also

Enfleurage

In cold enfleurage, a large glass plate called a chassis is smeared with a layer of animal fat, typically lard or tallow, and allowed to set. The botanical material, often petals or whole flowers, is then placed on the fat, and its scent is left to diffuse into the fat for 1-3 days. This process is repeated with fresh botanicals until the fat reaches the desired fragrance saturation.

Hot enfleurage involves heating solid fats and stirring botanical matter into them. Spent botanicals are strained and replaced with fresh material until the fat is saturated with fragrance. This method is considered the oldest procedure for preserving plant fragrance.

Once the fat is saturated with fragrance, it is called "enfleurage pomade". It can be sold as-is or further processed to extract the fragrant molecules. The pomade is washed or soaked in ethyl alcohol, separating the fragrance from the fat. The alcohol is then allowed to evaporate, leaving behind the absolute botanical fragrance. The spent fat is often used to make soaps.

To make perfume using enfleurage, one can follow these steps:

- Acquire lard or render suet into solid tallow to create the fat base.

- Melt the fat and strain it to remove impurities, ensuring it is scent-free.

- Pour the fat into a glass dish and let it harden, scoring the surface beforehand to aid fragrance absorption.

- Collect flowers or petals early in the morning when they are most fragrant, ensuring there is no greenery attached.

- Place the flowers on the fat, pressing them down with a glass dish that fits uniformly on top. Seal the dishes together and leave in a cool, dark area for 48 hours.

- Remove the spent flowers and repeat the process with fresh flowers 2-3 more times to strengthen the scent.

- Chop up the fragrant fat and place it in bottles with wire-and-ball stoppers, filling halfway.

- Pour 70% rubbing alcohol into the bottles and seal them. Store the bottles in a cool, dark place for 3 months to let the alcohol absorb the fragrance.

- After 3 months, strain out the fat and add a fixative like cedarwood oil to stabilise the scent. Rebottle for personal use.

Aromatherapy: Enhancing Your Space with Essential Oils

You may want to see also

Oil infusion

Step 1: Prepare Your Ingredients and Materials

- Herbs, spices, flowers, or plants of your choice. You can use either fresh or dried ingredients, but dried ingredients are recommended for beginners as fresh ingredients have a high moisture content that increases the risk of introducing mould into your oil.

- Carrier oil such as olive oil, almond oil, jojoba oil, or coconut oil.

- Clean, dry glass jars or bottles.

- Coffee filters, cheesecloth, or a sieve.

- Hot plate, double boiler, or pan/skillet (optional, for heating method).

Step 2: Prepare Your Herbs or Spices

- Wash and completely dry your herbs and spices.

- Bruise or rub the herbs, or toast the spices, to bring out the flavour.

Step 3: Infuse the Oils

- Place the herbs or spices into a clean, dry glass jar.

- Add oil until it completely covers the herbs or spices.

- Close the lid and place the jar on a sunny windowsill or another sunny spot.

- Swirl or shake the jar every day or so.

- For the heating method, place the jar on a hot plate and simmer for several hours, or heat the oil and spices in a skillet until the oil bubbles and the spices sizzle.

Step 4: Drain and Store the Oil

- After a week, drain the oil into a clean, dry jar using a sieve, cheesecloth, or coffee filter.

- Taste or smell the oil to see if the flavour or scent is strong enough.

- If you want a stronger infusion, add more herbs or spices to the oil, close the lid, and place it back in a sunny spot for another week.

- If you are happy with the infusion, pour the oil into a nice glass bottle and store it in a cool, dry place or in the refrigerator.

Unlocking the Secrets of Aroma in Ingredients

You may want to see also

Frequently asked questions

The simplest way to make aroma oils is through an oil infusion. This involves choosing a base oil with a mild scent, such as olive oil, jojoba oil, or almond oil, and combining it with the flowers, herbs, or spices of your choice.

You can use almost any garden herb for making aroma oils. Popular choices include lavender, rosemary, peppermint, thyme, and lemon balm. When it comes to spices, cinnamon, coriander, cumin, nutmeg, and cloves are common options. For flowers, roses, carnations, lavender, and violets are all great options.

First, chop or crush your chosen plant material to release its scent. Then, cover the plant material with your chosen base oil in a glass jar. Seal the jar and leave it to infuse for 24 hours or more, depending on the desired strength. Finally, strain the oil and discard the plant material.

Steam distillation involves boiling plant material until the essential oils separate from the plant and float on the water. You can collect the oil from the surface and store it in a glass bottle. This method requires a still, which you can purchase or build yourself.

Other methods for making aroma oils at home include solvent extraction, cold-press, and maceration. Solvent extraction involves soaking plant material in a solvent such as hexane or ethanol. Cold-press involves puncturing the rind of a fruit and using centrifugal force to separate the oil from the pulp. Maceration involves adding raw plant material to a maceration tank and soaking it in a carrier oil for several days or weeks.