Extracting the essence of flower fragrance is an art that involves capturing the delicate aroma of blooms. This process begins with selecting the right flowers at their peak freshness, ensuring a rich scent. Various methods can be employed, such as steam distillation, solvent extraction, or CO2 extraction, each requiring specific techniques to preserve the fragrance's complexity. The chosen method depends on the flower's nature and the desired outcome, whether it's a pure essential oil or a fragrant extract for cosmetics. Understanding these extraction techniques is key to unlocking the captivating scents of flowers and utilizing them in various industries.

What You'll Learn

- Distillation: Steam or water to extract volatile compounds

- Solvent Extraction: Use solvents like hexane to isolate fragrance

- Expression: Mechanical pressing to release essential oils

- Sol-Gel Process: Convert liquid to solid to capture fragrance

- Microextraction: Use hollow fibers to enhance fragrance extraction

Distillation: Steam or water to extract volatile compounds

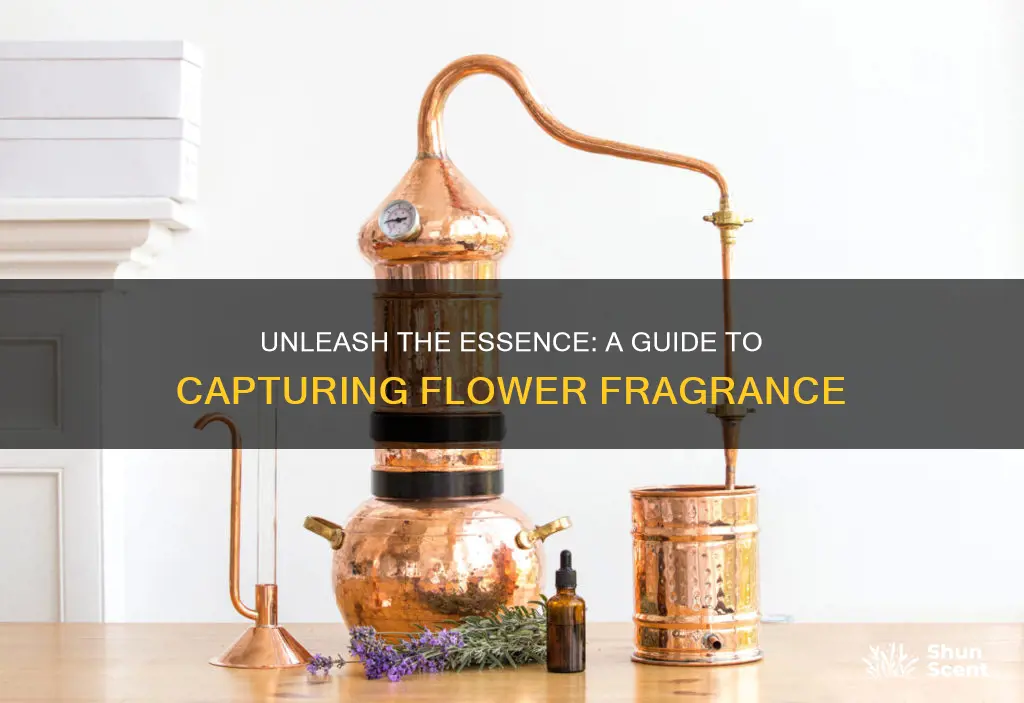

Distillation is a widely used technique in perfumery and essential oil extraction, offering a method to isolate and concentrate the volatile compounds responsible for the characteristic fragrance of flowers. This process involves the use of steam or water to extract these aromatic molecules, which are then collected and purified. Here's a detailed look at how distillation can be employed for this purpose:

Steam Distillation: This method is particularly effective for extracting fragrances from delicate flowers that may lose their aroma if exposed to high temperatures. The process begins by passing steam through the floral material, typically fresh or dried petals or buds. The steam gently carries the volatile compounds, including essential oils and fragrance molecules, from the plant material. As the steam-infused compounds are drawn off, they are then cooled and condensed into a liquid, known as the distillate. This distillate is a concentrated form of the flower's fragrance, containing a blend of various aromatic compounds. The beauty of steam distillation is its ability to preserve the natural scent profile of the flower, ensuring that the extracted fragrance remains true to the original source.

Water Distillation: Water distillation is another gentle process that can be used to capture the essence of flowers. It involves submerging the floral material in water and then heating it. As the water is heated, it creates a vapor that carries the volatile compounds. These aromatic molecules then condense back into a liquid, forming the distillate. This method is advantageous for flowers that may not be suitable for steam distillation due to their sensitivity to heat. Water distillation is a more delicate process, allowing for the extraction of a wide range of fragrance components, including those with lower boiling points. The resulting distillate can be further refined to create a pure and potent flower essence.

Both steam and water distillation techniques require careful control of temperature and pressure to ensure the efficient extraction of volatile compounds. The choice between the two methods depends on the specific flower species and the desired outcome. For instance, flowers with higher resilience to heat might benefit from steam distillation, while more delicate blooms may require the gentler approach of water distillation.

In perfumery, the distillates obtained through these distillation processes serve as valuable ingredients for creating fragrances. The extracted volatile compounds can be blended with other aromatic materials to craft unique and captivating scents. This natural approach to fragrance creation ensures that the final product captures the essence and beauty of the original flower.

Amber Scents in Summer: Do They Work?

You may want to see also

Solvent Extraction: Use solvents like hexane to isolate fragrance

Solvent extraction is a widely used technique in the fragrance industry to isolate and extract volatile compounds, including the delicate and complex fragrances found in flowers. This method involves the use of specific solvents, such as hexane, to dissolve and separate the fragrant molecules from the plant material. Here's an overview of the process:

The first step in solvent extraction is the preparation of the raw material. Fresh flowers or plant parts containing the desired fragrance are carefully selected and cleaned to remove any impurities or debris. It is crucial to work with high-quality material to ensure the purity of the extracted fragrance. The plant material is then finely chopped or ground to increase the surface area, allowing for better contact with the solvent.

Hexane, a non-polar solvent, is commonly employed due to its ability to dissolve non-polar molecules. It is carefully measured and added to the ground plant material in a controlled environment. The mixture is then agitated or stirred to facilitate the extraction process. During this step, the fragrant compounds, such as terpenes and esters, present in the flowers, dissolve into the hexane layer. The non-polar nature of hexane allows it to selectively extract these compounds while leaving behind other plant materials.

After the extraction, the mixture is separated into two layers: the hexane layer containing the fragrance and the aqueous (water) layer. This separation is typically achieved through a process called liquid-liquid extraction, where the layers are carefully decanted or separated using a separating funnel. The hexane layer, now enriched with the flower fragrance, is then collected and further processed to remove any remaining water or impurities.

To purify the extracted fragrance, various techniques can be employed. One common method is distillation, where the hexane is distilled under controlled conditions to separate it from the fragrant compounds. The distilled hexane can then be re-used, while the fragrant compounds are collected and further refined. Additionally, chromatography techniques can be utilized to separate and isolate individual fragrance components, allowing for the creation of specific fragrance profiles.

Solvent extraction using hexane is a precise and controlled process, requiring careful attention to detail. It is an efficient method for obtaining high-quality flower fragrances, which can then be used in various industries, including perfumery, cosmetics, and even food flavoring. This technique showcases the intricate art of fragrance extraction, where solvents play a crucial role in unlocking the hidden aromas within flowers.

Using Diffuser Scents in Soap: A Creative Fragrance Solution

You may want to see also

Expression: Mechanical pressing to release essential oils

Mechanical pressing is a popular and effective method to extract the delicate fragrance of flowers, capturing their essence and releasing it as essential oils. This technique is often used in the perfumery and aromatherapy industries to create natural, pure fragrances. The process involves applying pressure to the floral material, which helps to break down the plant's cellular structure, allowing the volatile compounds, or essential oils, to be released.

The first step in this extraction method is the preparation of the floral material. Fresh flowers are carefully selected and cleaned to remove any dirt or debris. It is crucial to use flowers at their peak freshness to ensure the highest quality of essential oil. The petals and sometimes the entire flower, including the sepals and petals, are then carefully laid out on a screen or mesh. This setup allows for good airflow and facilitates the pressing process.

Mechanical pressing machines are designed to apply controlled pressure to the floral material. These machines typically consist of a pressing plate and a counterweight or a mechanical arm that applies force. The flowers are placed on the pressing plate, and the machine applies pressure, often in a gentle, continuous motion. The pressure helps to extract the essential oils, which are then collected. This process can be done manually or with automated machines, depending on the scale of production.

During the pressing, the essential oils are released from the floral material and rise due to their volatility. These oils are then collected in a separate container placed below the pressing plate. The collected oils are a concentrated form of the flower's fragrance, capturing its unique scent profile. The process can be optimized by controlling factors such as pressure, temperature, and the duration of the pressing, which can vary depending on the flower species and the desired oil concentration.

After the pressing, the extracted essential oil can be further refined and purified to create a high-quality, pure fragrance. This may involve distillation or other purification methods to ensure the oil is free from impurities and retains its natural properties. Mechanical pressing is a gentle and efficient way to unlock the fragrant secrets of flowers, providing a sustainable and natural source of fragrances for various industries.

The Longevity of Dana Fragrances: Are They Long-Lasting?

You may want to see also

Sol-Gel Process: Convert liquid to solid to capture fragrance

The sol-gel process is a fascinating technique that can be utilized to capture and preserve the delicate fragrance of flowers. This method involves a transformation from a liquid state to a solid, creating a unique and effective way to extract and retain the essence of floral scents. Here's an overview of how this process can be applied to your task:

In the realm of fragrance extraction, the sol-gel process offers a versatile approach. It begins with a liquid solution containing the desired fragrance compounds, often derived from floral sources. The key to this process lies in the gradual addition of a gelating agent, typically an organic or inorganic compound, which initiates a chemical reaction. This reaction leads to the formation of a three-dimensional network, trapping the volatile fragrance molecules within a solid matrix. The choice of gelating agent is crucial, as it determines the final properties of the solid product. For instance, silica-based gels are commonly used due to their stability and ability to form a robust network.

As the process unfolds, the liquid gradually transforms into a semi-solid or solid state, depending on the desired outcome. This transformation is carefully controlled to ensure the fragrance molecules are effectively captured. The gelation process can be optimized by adjusting factors such as temperature, pH, and the concentration of the gelating agent. By fine-tuning these parameters, one can achieve a highly selective and efficient extraction of the target fragrance compounds.

One of the advantages of the sol-gel process is its ability to provide a stable and long-lasting fragrance. The solid matrix formed encapsulates the fragrant molecules, preventing their evaporation and ensuring a sustained release over time. This makes it an ideal method for creating scented materials, such as potpourri or air fresheners, where a prolonged fragrance release is desired. Furthermore, the sol-gel process allows for customization, enabling the creation of solid fragrances with specific properties, such as color, texture, and melting point, to cater to various applications.

To implement this process, one would typically start with a carefully selected liquid fragrance extract, ensuring it contains the desired floral notes. The liquid is then mixed with the chosen gelating agent, and the mixture is allowed to incubate under controlled conditions. During this incubation, the gelation reaction occurs, and the fragrance molecules become embedded in the solid structure. Post-processing steps may include drying, curing, or further purification to achieve the final solid fragrance product.

In summary, the sol-gel process provides an innovative way to capture and preserve flower fragrance. By converting a liquid extract into a solid matrix, this technique ensures the longevity and stability of the fragrance. With its versatility and ability to tailor the final product, the sol-gel process is a valuable tool for fragrance extraction and creation, offering a unique approach to harnessing the beauty of floral scents.

Fragrance and Skin: The Itch Connection

You may want to see also

Microextraction: Use hollow fibers to enhance fragrance extraction

The process of extracting the delicate and captivating fragrance from flowers is an art that has been refined over centuries. One innovative technique that has emerged in recent years is microextraction, which utilizes hollow fibers to enhance the extraction of volatile compounds, resulting in a more efficient and effective process. This method is particularly useful for capturing the intricate aroma profiles of flowers, ensuring a high-quality fragrance extraction.

Hollow fibers, often made from polymeric materials, play a crucial role in this process. These fibers are designed with a unique structure, featuring a hollow core and a porous wall. The hollow design allows for the creation of a large surface area, providing ample space for the interaction between the fragrance compounds and the extraction medium. When flowers are subjected to this process, the volatile organic compounds (VOCs) responsible for the scent are released and come into contact with the fibers.

The key advantage of using hollow fibers is their ability to facilitate a high degree of mass transfer. As the fragrance compounds diffuse through the fiber wall, they are effectively separated from the bulk of the floral material. This separation is essential to prevent the re-absorption of the extracted compounds, ensuring a pure and concentrated fragrance. The porous nature of the fibers also enables a higher loading capacity, allowing for the extraction of a larger volume of fragrance from a relatively small amount of floral material.

In the microextraction process, the hollow fibers are often arranged in a specific configuration, such as a packed bed or a membrane module. This arrangement maximizes the contact time between the fragrance compounds and the fibers, further enhancing the extraction efficiency. The fibers can be made permeable to the desired compounds, allowing for selective extraction, which is crucial for achieving the desired fragrance profile.

This technique offers several advantages over traditional extraction methods. Firstly, it provides a higher extraction rate, making it more time-efficient. The hollow fiber structure also reduces the risk of contamination, as the extracted fragrance is isolated from the floral material. Additionally, microextraction can be easily scaled up or down, making it adaptable to various production requirements. By utilizing hollow fibers, the process becomes more sustainable and environmentally friendly, as it minimizes waste and optimizes the use of resources.

Bissell Fragrance Discs: Unlocking Freshness, Duration, and Value

You may want to see also

Frequently asked questions

There are several methods to extract flower fragrance, including solvent extraction, steam distillation, and CO2 extraction. Each method has its advantages and is chosen based on the type of flower and desired fragrance. Solvent extraction is a common and cost-effective method, while steam distillation is gentle and preserves the natural fragrance. CO2 extraction is a more advanced technique, offering high-quality results.

Yes, it is possible to extract flower fragrance at home using simple techniques. For small-scale extraction, you can use a still or a simple distillation setup. However, for larger quantities or more complex fragrances, it is recommended to use professional equipment and techniques to ensure purity and consistency.

Selecting the right flowers is crucial for a successful extraction. Consider the flower's fragrance intensity, color, and availability. Some flowers, like roses, lavender, and jasmine, are commonly used for their strong and desirable fragrances. You can also experiment with different flower varieties to create unique blends. Drying or freezing the flowers before extraction can enhance their fragrance concentration.

Various solvents can be used for extraction, including ethanol, hexane, and essential oils. Ethanol is a popular choice due to its effectiveness and safety. It is a polar solvent that can dissolve non-polar compounds, making it ideal for extracting fragrant oils from flowers. Hexane is another solvent, but it is less commonly used due to its potential health risks.

Proper storage is essential to maintain the quality and longevity of the extracted fragrance. Store the fragrance in a cool, dark place, away from direct sunlight and heat sources. Glass or amber bottles are recommended to protect the fragrance from degradation. Keep the container tightly sealed to prevent air exposure, which can cause oxidation. Regularly check the fragrance for any changes in color or smell, and replace it if necessary.