Determining the fragrance load in a product is a crucial step in the formulation process for creating appealing and effective fragrances. The fragrance load refers to the concentration of fragrance ingredients in a product, which directly impacts the scent's intensity, longevity, and overall performance. This process involves understanding the specific requirements of the fragrance, the base product, and the desired scent profile. It requires careful consideration of factors such as the type of fragrance (top, middle, or base notes), the stability of the ingredients, and the compatibility with the product's other components. By accurately assessing the fragrance load, formulators can ensure that the final product delivers the intended olfactory experience while maintaining the integrity and safety of the ingredients.

What You'll Learn

- Ingredient Analysis: Identify and quantify key fragrance ingredients in a formula

- Olfactometric Techniques: Use methods like gas chromatography to measure scent concentration

- Sensory Evaluation: Train a panel to assess fragrance intensity and quality

- Product Testing: Apply fragrance to samples and measure performance in real-world conditions

- Regulatory Compliance: Ensure fragrance loads meet safety standards and regulations

Ingredient Analysis: Identify and quantify key fragrance ingredients in a formula

To determine the fragrance load in a formula, a comprehensive ingredient analysis is essential. This process involves a detailed examination of the composition to identify and quantify the key fragrance ingredients. Here's a step-by-step guide to achieving this:

- Ingredient Identification: Begin by creating a comprehensive list of all the ingredients present in the fragrance formula. This includes both the primary fragrance notes and any supporting ingredients. For instance, in a perfume, you might have top notes like citrus, middle notes such as rose or jasmine, and base notes like musk or amber. Each ingredient should be clearly labeled and categorized.

- Concentration and Proportion: Determine the concentration of each ingredient in the formula. Fragrance ingredients are typically used in various concentrations, which can significantly impact the overall scent. Measure the percentage or weight of each ingredient relative to the total formula. For example, a top note might be present in a higher concentration to create an immediate sensory effect, while base notes are often used in smaller amounts to provide depth and longevity.

- Key Ingredient Selection: Identify the critical fragrance ingredients that contribute the most to the overall scent profile. These are the ingredients that define the unique character of the fragrance. For instance, in a cologne, the citrus notes might be the primary fragrance load, while in a perfume, it could be the floral or woody notes. Quantify these key ingredients by calculating their individual contributions to the total fragrance load.

- Sensory Evaluation: Conduct sensory tests to validate the ingredient analysis. This step is crucial as it provides practical insights into the fragrance's performance. Evaluate the formula's scent profile by applying it to a sample material and assessing the intensity and balance of the fragrance notes. Compare the results with the theoretical calculations to ensure accuracy.

- Adjustments and Formulation: Based on the analysis, make adjustments to the formula to optimize the fragrance load. If certain ingredients are underperforming or overpowering others, consider modifying their proportions or replacing them with alternative compounds. This iterative process ensures the final product has a well-balanced and desirable scent.

By following these steps, perfumers and formulators can precisely determine the fragrance load, ensuring that the final product meets the desired olfactory experience. This ingredient analysis is a critical aspect of fragrance creation, allowing for the development of unique and captivating scents.

Enhance Your Bath Experience: A Guide to Adding Fragrance

You may want to see also

Olfactometric Techniques: Use methods like gas chromatography to measure scent concentration

Olfactometric techniques are specialized methods employed in the fragrance industry to quantify and analyze the concentration of scents in various products. One of the most powerful tools in this field is gas chromatography (GC), a technique that has revolutionized the way we measure and understand fragrance loads. This method is particularly useful for determining the exact amount of fragrance compounds present in a given sample, allowing for precise control and formulation in the creation of perfumes and fragrances.

Gas chromatography works by separating and analyzing volatile compounds, which are essential in the fragrance industry. The process begins with the vaporization of the sample, which is then introduced into the GC instrument. Here, the sample is separated into individual components based on their interaction with a stationary phase and a mobile phase. The mobile phase, typically an inert gas like helium, carries the separated compounds through the column, where they are further analyzed. This separation is crucial as it allows for the identification and quantification of each fragrance compound, providing a detailed profile of the scent.

The power of GC lies in its ability to detect and quantify even trace amounts of fragrance compounds. By utilizing sensitive detectors, such as flame ionization detectors (FID) or mass spectrometers, the instrument can identify and measure the concentration of individual scent molecules. This level of precision is vital for fragrance formulation, as it ensures that the final product contains the desired amount of each fragrance component. For instance, in the creation of perfumes, GC can help achieve the perfect balance of notes, ensuring that the top, middle, and base notes are well-represented and blended harmoniously.

Olfactometric techniques, including GC, offer a scientific approach to fragrance development. By providing quantitative data, these methods enable perfumers and formulators to make informed decisions about ingredient selection and concentration. This is especially important in the creation of high-quality fragrances, where the right balance of scents can make all the difference. With the use of GC, the industry can ensure consistency and quality, meeting the high standards expected by consumers.

In summary, gas chromatography is a powerful olfactometric technique that plays a critical role in determining fragrance loads. Its ability to separate, identify, and quantify scent compounds provides an invaluable tool for the fragrance industry. Through the use of GC, perfumers can create unique and captivating fragrances, ensuring that each product meets the desired scent profile and quality standards. This scientific approach to fragrance formulation continues to drive innovation and excellence in the world of perfumery.

Fragrance Delivery in France: Is It Possible?

You may want to see also

Sensory Evaluation: Train a panel to assess fragrance intensity and quality

To effectively train a panel for sensory evaluation of fragrance intensity and quality, it's crucial to establish a structured and comprehensive training process. This involves not only selecting the right individuals but also providing them with the necessary tools and knowledge to perform their tasks accurately. Here's a step-by-step guide to achieving this:

- Panel Selection and Recruitment: Begin by identifying individuals who possess a keen sense of smell and a natural affinity for fragrances. This could include perfumers, aromatherapists, or individuals with a background in chemistry or related fields. Look for those who can discern subtle differences in scents and have a good understanding of fragrance terminology. It's essential to have a diverse panel to capture a wide range of sensory perceptions.

- Sensory Training: Conduct intensive training sessions to educate the panel about fragrance evaluation. Start by familiarizing them with the concept of fragrance intensity, which refers to the perceived strength or concentration of a scent. Teach them how to recognize and differentiate between various fragrance categories, such as top, middle, and base notes. Provide practical exercises where they can identify and describe different fragrances, focusing on their unique characteristics.

- Quality Assessment: Train the panel to assess fragrance quality, which encompasses aspects like aroma, longevity, and overall appeal. Instruct them to evaluate fragrances based on criteria such as freshness, complexity, and whether the scent is well-balanced or overly dominant. Encourage them to consider the fragrance's ability to evolve over time and its overall sensory experience. Practical exercises can include blindfold tests to assess their ability to identify fragrances based solely on scent.

- Standardization and Consistency: Establish standardized evaluation protocols to ensure consistency in the panel's assessments. Develop a comprehensive checklist or rating scale that covers various sensory attributes, including intensity, quality, and overall preference. This standardization will enable you to compare results across different fragrances and panels, ensuring reliable and reproducible data.

- Regular Refinement: Sensory evaluation is an ongoing process, and it's essential to regularly update and refine the training. Conduct periodic retraining sessions to keep the panel's skills sharp and introduce new fragrances for evaluation. This ensures that the panel stays current with industry trends and can accurately assess the latest fragrance innovations.

- Feedback and Communication: Foster an environment of open communication and feedback within the panel. Encourage members to share their perceptions and insights, creating a collaborative atmosphere. This collective intelligence can lead to a more nuanced understanding of fragrance characteristics and help identify any biases or trends in their assessments.

By following these steps, you can create a highly skilled and reliable panel for sensory evaluation, capable of assessing fragrance intensity and quality with precision and consistency. This process is vital for fragrance manufacturers and formulators to ensure their products meet consumer expectations and market demands.

Dr. Squatch's Fragrance: A Deep Dive into the Scent

You may want to see also

Product Testing: Apply fragrance to samples and measure performance in real-world conditions

When it comes to product testing and understanding the performance of fragrances, applying the scent to samples and evaluating its endurance in real-world scenarios is a crucial step. This process allows you to gain valuable insights into how the fragrance will behave in various environments and on different materials. Here's a detailed guide on how to approach this aspect of fragrance load determination:

Sample Preparation: Begin by creating a diverse set of samples that represent the products or materials you intend to use the fragrance on. For instance, if you're testing a perfume, you might prepare vials or bottles of the fragrance. For fabrics, create swatches or small fabric pieces. Ensure that these samples are representative of the final product to get accurate results.

Application Technique: The method of applying the fragrance is critical to obtaining reliable data. For liquids or sprays, use a precise sprayer or a small dropper to apply an even layer onto the sample. For solids like candles or incense, carefully melt or rub a small amount onto the surface. Consistency in application is key to ensuring comparable results.

Real-World Conditions Simulation: Replicating real-world conditions is essential for accurate testing. Set up an environment that mimics the typical usage scenarios. For example, if the fragrance is intended for clothing, expose the treated fabric to various temperatures, humidity levels, and even simulate washing conditions. For personal care products, consider the skin's natural oils and the effects of different activities (e.g., sweating, rubbing) on the fragrance's longevity.

Performance Measurement: Define clear criteria to measure the fragrance's performance. This could include factors such as scent intensity over time, longevity, and the fragrance's ability to withstand various conditions without fading or altering its character. For instance, you might assess how the fragrance holds up after a certain number of wears or washes. Take notes on the duration of scent detection and any changes in its quality.

Data Analysis: After testing, analyze the results to determine the fragrance load. Compare the initial scent intensity with the remaining fragrance after the specified conditions have been met. Look for patterns and trends in performance across different samples and conditions. This analysis will help you understand the fragrance's stability, its ability to persist, and any potential issues like sourness or harshness that may arise over time.

By following these steps, you can systematically evaluate fragrance performance, ensuring that the final product meets the desired scent standards and provides a satisfying experience for consumers. This approach to product testing is essential for the development and refinement of fragrances in various industries.

Bay Rum's Aromatic Journey: A Guide to Captivating Scent Descriptions

You may want to see also

Regulatory Compliance: Ensure fragrance loads meet safety standards and regulations

When it comes to the formulation of fragrances and perfumed products, regulatory compliance is of utmost importance to ensure the safety and well-being of consumers. Fragrance loads, which refer to the concentration of fragrances in a product, play a critical role in meeting these standards. Regulatory bodies, such as the European Union's Cosmetics Regulation (EC) No 1223/2009 and the U.S. Food and Drug Administration (FDA), have established guidelines and restrictions to safeguard public health. These regulations often dictate the maximum allowable levels of fragrance ingredients, especially those that may be potentially hazardous.

To ensure compliance, manufacturers must carefully determine the fragrance load in their products. This process involves several key steps. Firstly, a comprehensive understanding of the fragrance ingredients is essential. Each ingredient should be evaluated for its potential risks, including any known allergens, irritants, or sensitizers. This evaluation is typically based on scientific studies, toxicological data, and existing research. By gathering and analyzing this information, manufacturers can identify any potential issues and make informed decisions regarding the fragrance load.

Secondly, a thorough assessment of the product's intended use and target audience is necessary. Different products, such as skincare, hair care, or personal care items, may have varying regulatory requirements. For instance, products intended for sensitive skin or those targeting children might have stricter fragrance restrictions. Understanding the product's purpose and the demographics it caters to is crucial in determining the appropriate fragrance load. This step ensures that the fragrance is used in a manner that aligns with regulatory guidelines and consumer safety.

The next step is to employ appropriate analytical techniques to measure the fragrance load accurately. This may involve various methods such as gas chromatography-mass spectrometry (GC-MS), high-performance liquid chromatography (HPLC), or other specialized techniques. These tools enable the quantification of fragrance ingredients, allowing manufacturers to precisely determine their concentration in the product. By utilizing these analytical methods, companies can ensure that the fragrance load meets the required regulatory limits.

Lastly, it is essential to maintain detailed documentation and records throughout the process. This includes documenting the rationale behind fragrance ingredient choices, the evaluation of potential risks, and the analytical data supporting the fragrance load determination. Proper documentation ensures transparency and facilitates regulatory audits, demonstrating that the product formulation adheres to the necessary safety standards. Additionally, it provides a reference for future product development and reformulation, ensuring consistent compliance.

Fragrance Oil Burners: Are They Safe to Use?

You may want to see also

Frequently asked questions

Fragrance load refers to the concentration or amount of fragrance oil used in a product, such as perfume, lotion, or candle. It is a measure of the intensity and longevity of the scent.

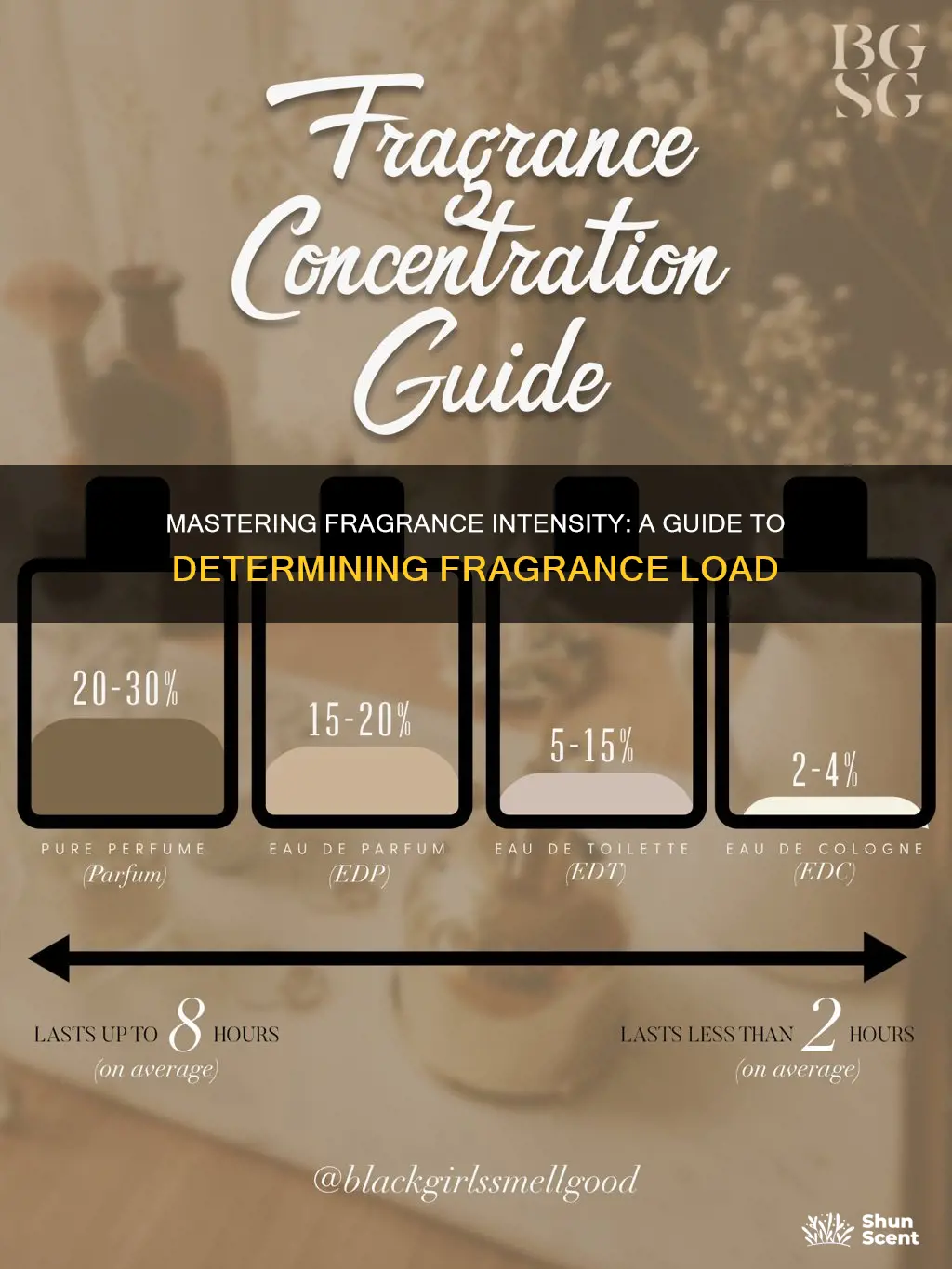

Fragrance load is typically measured in percentages or by weight. The concentration can vary depending on the product and the desired scent strength. For example, a perfume may have a higher fragrance load compared to a body lotion.

Determining the fragrance load is crucial for product development and ensuring customer satisfaction. It helps in achieving the desired scent intensity, longevity, and overall quality. A well-balanced fragrance load can create a pleasant and consistent aroma, while an excessive load may cause the scent to be overpowering, while an insufficient load might result in a faint or quickly fading fragrance.