Creating high-fragrance candles is an art that combines creativity and technical precision. This process involves selecting high-quality fragrances, blending them with wax, and ensuring the final product has a strong, long-lasting scent. The key to success lies in understanding the properties of different fragrances, wax types, and additives, as well as mastering the art of mixing and pouring. By following a structured approach, you can create candles that not only look beautiful but also fill your space with delightful aromas.

What You'll Learn

- Wax Selection: Choose the right wax for fragrance retention and melting point

- Fragrance Oils: Use high-quality oils for rich, long-lasting scents

- Dyeing: Add color safely with dyes or pigments

- Wick Placement: Center wicks for even burning and stability

- Pouring Technique: Control temperature and speed for a clean finish

Wax Selection: Choose the right wax for fragrance retention and melting point

When it comes to crafting high-fragrance candles, the choice of wax is a critical factor that significantly influences the overall quality and performance of your candles. The right wax blend can enhance fragrance retention and ensure a smooth, long-lasting melt. Here's a detailed guide on selecting the ideal wax for your candle-making endeavors:

Paraffin Wax: This is a popular choice for candle-making due to its low cost and versatility. Paraffin wax has a relatively low melting point, typically around 120-180°F (49-82°C), making it easy to work with. It provides a clean and even burn, which is essential for a high-quality candle. However, paraffin wax may not offer the best fragrance retention. To improve this, consider blending it with other waxes or adding a small amount of a fragrance-enhancing additive.

Soy Wax: Derived from soybeans, soy wax is a natural and renewable option. It boasts excellent fragrance retention properties, allowing the scent to permeate the wax and create a rich, aromatic experience. Soy wax has a higher melting point compared to paraffin, usually around 125-180°F (52-82°C), which results in a longer burning time. This makes it an ideal choice for those seeking candles that last longer. Additionally, soy wax is known for its smooth and creamy texture, ensuring a clean and even burn.

Beeswax: A natural wax with a higher melting point of approximately 145-160°F (63-71°C), beeswax is a premium option for candle-makers. It is highly regarded for its ability to enhance the fragrance of your candles, ensuring a strong and long-lasting scent. Beeswax adds a unique, natural aroma to the candle and contributes to a cleaner burn. When blended with other waxes, it can improve the overall fragrance performance.

Blending Waxes: Consider experimenting with wax blends to achieve the desired fragrance retention and melting point. For instance, combining soy wax with a small percentage of paraffin can create a longer-lasting candle while maintaining the soy wax's excellent fragrance-holding properties. Blending beeswax with paraffin can also result in a more stable and long-lasting candle. Remember, the key is to find the right balance that suits your specific candle-making goals.

In summary, the wax selection is a crucial step in crafting high-fragrance candles. By understanding the properties of different waxes, you can make informed decisions to create candles with exceptional fragrance retention and melting performance. Experimentation and blending techniques can further enhance the overall quality of your candle-making process.

Long-Lasting Scent: Discovering the Endurance of Lampe Berger Perfumes

You may want to see also

Fragrance Oils: Use high-quality oils for rich, long-lasting scents

When crafting high-fragrance candles, the choice of fragrance oils is paramount. Opting for high-quality oils is essential to achieving rich, long-lasting scents that will fill your space with delightful aromas. Here's a guide to understanding and utilizing fragrance oils effectively:

Selecting Fragrance Oils: High-quality fragrance oils are the cornerstone of your candle-making endeavor. These oils are carefully crafted to provide an intense and enduring scent. Look for reputable suppliers that offer a wide range of natural and synthetic fragrances. Natural oils, derived from plants, offer a pure and authentic scent, while synthetic oils provide consistency and longevity. Choose oils that are specifically designed for candle-making, as they are formulated to withstand the heat of the wax during the pouring process.

Concentration and Strength: Fragrance oils come in various concentrations, typically ranging from 10% to 50%. Higher concentrations mean a more potent scent. For candles, a concentration of around 10-15% is ideal, ensuring the fragrance is strong enough to be noticed but not overpowering. Thinner oils might require a higher percentage to achieve the desired scent throw, while thicker oils can be used at lower concentrations.

Blending and Customization: Fragrance oils offer endless possibilities for customization. You can create unique blends by mixing different oils to achieve a signature scent. Start with a base note, such as vanilla or musk, and then layer other notes like citrus or floral to create a complex aroma. Experiment with various combinations to find your perfect fragrance. Remember, a little goes a long way, so add oils gradually and test the scent regularly.

Sustainability and Safety: When sourcing fragrance oils, prioritize suppliers who prioritize sustainability and ethical practices. Look for companies that use renewable resources and minimize environmental impact. Additionally, ensure that the oils are free from harmful chemicals and comply with safety standards, especially if you plan to use them in large quantities or for other craft projects.

Application and Usage: When adding fragrance oils to your candle-making process, follow a precise recipe. Measure the oils accurately and mix them thoroughly with the wax. Heat the wax gently to ensure even distribution, but be cautious not to overheat, as it can alter the scent. Pour the wax into your chosen container, allowing the fragrance to infuse. This process ensures that the scent is evenly distributed throughout the candle, creating a consistent and captivating aroma.

Fragrance Oils vs. Perfume: Which Scents Last Longer?

You may want to see also

Dyeing: Add color safely with dyes or pigments

Dyeing candles can be a fun and creative way to add color and visual appeal to your handmade creations. When it comes to achieving vibrant and long-lasting colors in your scented candles, the choice of dyes and pigments is crucial. Here's a guide to help you master the art of dyeing candles safely and effectively:

Understanding Candle Wax and Dye Compatibility:

Before you begin, it's essential to know that not all dyes and pigments are compatible with candle wax. Different wax types, such as soy, beeswax, or paraffin, may require specific dyeing techniques. For instance, soy wax is known for its excellent dye absorption, while beeswax can be more challenging to dye due to its natural color and consistency. Research the specific wax you're using to determine the best dyeing methods.

Choosing the Right Dyes and Pigments:

- Dyes: Natural plant-based dyes, like those derived from flowers, leaves, or berries, are popular choices for candle making. These dyes often provide subtle, earthy tones. For more vibrant colors, consider synthetic dyes, which offer a wide range of hues. Always opt for food-grade or candle-safe dyes to ensure the safety of your finished product.

- Pigments: Powdered pigments are another excellent option for candle dyeing. They provide intense colors and are often used in combination with dyes for a unique effect. Look for lightfast pigments, which are less likely to fade over time.

Safety Precautions:

- Always wear gloves when handling dyes and pigments to avoid skin irritation.

- Work in a well-ventilated area or outdoors to prevent inhaling fumes.

- Keep dyes and pigments away from children and pets.

- Test a small amount of dye or pigment on a scrap of wax before adding it to your candle batch to ensure the desired color is achieved.

Dyeing Techniques:

- Direct Application: For liquid dyes, simply add a small amount to the melted wax and stir well. This method is straightforward but may result in uneven color distribution.

- Infusion Method: This technique involves infusing the dye into the wax by simmering it together. Start with a small amount of wax and dye, then gradually add more wax, stirring continuously. This method ensures a more consistent color.

- Pigment Mixing: When using pigments, mix them with a small amount of wax melt or a carrier oil to create a paste. Then, add this paste to your wax and stir until the desired color is achieved.

Remember, practice makes perfect when it comes to candle dyeing. Experiment with different dyes, pigments, and techniques to create unique, fragrant candles that will delight your customers or enhance your home decor.

Mastering the Art of Oil Fragrance: Tips for a Sensual Experience

You may want to see also

Wick Placement: Center wicks for even burning and stability

Wick placement is a critical step in the art of candle-making, especially when aiming for high-quality, long-lasting fragrances. The position of the wick directly influences how the candle burns, affecting both its appearance and the intensity of the scent. One of the most important techniques to master is placing the wick at the center of the candle.

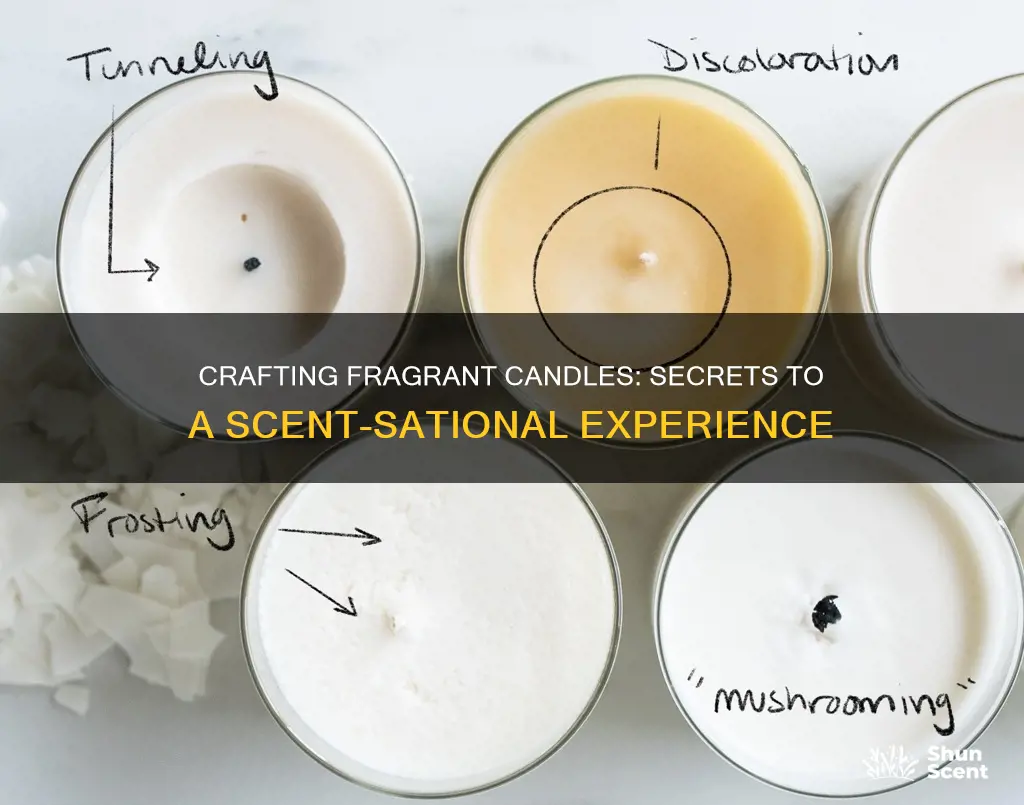

When you center the wick, you ensure that the flame has an equal distribution of heat and wax, allowing for a more even burn. This technique is particularly crucial for fragrance-rich candles, as it helps to release the aroma evenly, creating a consistent and captivating scent throughout the candle's life. An off-center wick can lead to uneven burning, with some areas melting faster than others, potentially causing the candle to smoke or leave uneven residue.

To achieve the perfect center placement, start by carefully inserting the wick into the pre-drilled hole in the candle's container. Ensure the wick is straight and centered, with the tab or anchor at the bottom of the container. You can use a wick sticker or a small piece of tape to temporarily secure the wick in place while it sets. This step requires precision and patience to get it right.

The benefits of central wick placement are twofold. Firstly, it promotes a clean and controlled burn, reducing the likelihood of the flame drifting or the candle smoking. Secondly, it ensures that the fragrance is distributed evenly, creating a rich and consistent aroma. This technique is especially important for high-fragrance candles, as it allows the scent to permeate the room without being too overpowering or uneven.

Mastering the art of wick placement is a key skill for any candle enthusiast or artisan. By centering the wick, you set the foundation for a high-quality, long-lasting candle that not only looks appealing but also fills your space with a delightful fragrance. This simple yet effective technique is a cornerstone of candle-making, ensuring your creations burn beautifully and scent your surroundings harmoniously.

Bath and Body Works Fragrances: Do They Expire?

You may want to see also

Pouring Technique: Control temperature and speed for a clean finish

Pouring candles is an art that requires precision and control, especially when aiming for a high-quality, fragrance-rich finish. The temperature and speed at which you pour the wax are critical factors that can make or break the final product. Here's a detailed guide on mastering the pouring technique:

Temperature Control: The temperature of the wax is a crucial element in achieving a clean and even pour. Start by heating your wax to the appropriate temperature. For soy wax, a common range is between 180°F to 190°F (82°C to 88°C). This temperature ensures the wax is fluid enough to pour but not too hot, which could cause it to smoke or alter the fragrance. Use a double boiler or a dedicated wax warmer to maintain a consistent temperature. As you pour, aim for a steady, controlled flow rather than a rapid pour. This controlled temperature prevents the wax from becoming too thick or too thin, ensuring a smooth and even surface.

Speed and Technique: Pouring speed is essential to creating a clean finish. Begin pouring when the wax is at the desired temperature, and move your container or mold in a steady, controlled motion. Avoid rapid, jerky movements as they can create imperfections and voids in the candle. The goal is to create a seamless, continuous pour. As you near the edge of the container, slightly reduce the speed to allow the wax to level off and form a smooth surface. This technique ensures that the candle has a professional, polished look. Practice this motion until it becomes second nature, as consistency is key to producing high-quality candles.

Consistency and Practice: Consistency in temperature and speed will lead to consistent results. Practice pouring in a well-ventilated area to avoid any potential hazards. With time and experience, you'll develop a sense of the right pour speed and temperature for your specific wax and fragrance combinations. Remember, the art of candle making is both a science and a creative process, and mastering the pouring technique is a significant step towards creating exquisite, high-fragrance candles.

Fragrance: A Powerful Portal to Memories and Emotions

You may want to see also

Frequently asked questions

The primary ingredients for crafting scented candles include a wax base (such as soy wax or paraffin wax), a fragrance or essential oil, a wick, and a container. You can also add dyes or pigments for color if desired.

Selecting the perfect fragrance is essential for creating a high-quality candle. Consider the scent family you want (e.g., floral, fruity, woody) and choose an oil that aligns with your preferences. Ensure the fragrance oil is of good quality and suitable for candle-making, as some oils may cause discoloration or accelerate the wax.

Start by melting the wax in a double boiler or a dedicated wax melter. Once it reaches the desired temperature, remove it from the heat and add your chosen fragrance oil, stirring gently to combine. Then, quickly but carefully pour the wax into your container, ensuring the wick is centered. Allow the candle to cool and harden before enjoying your handmade creation.