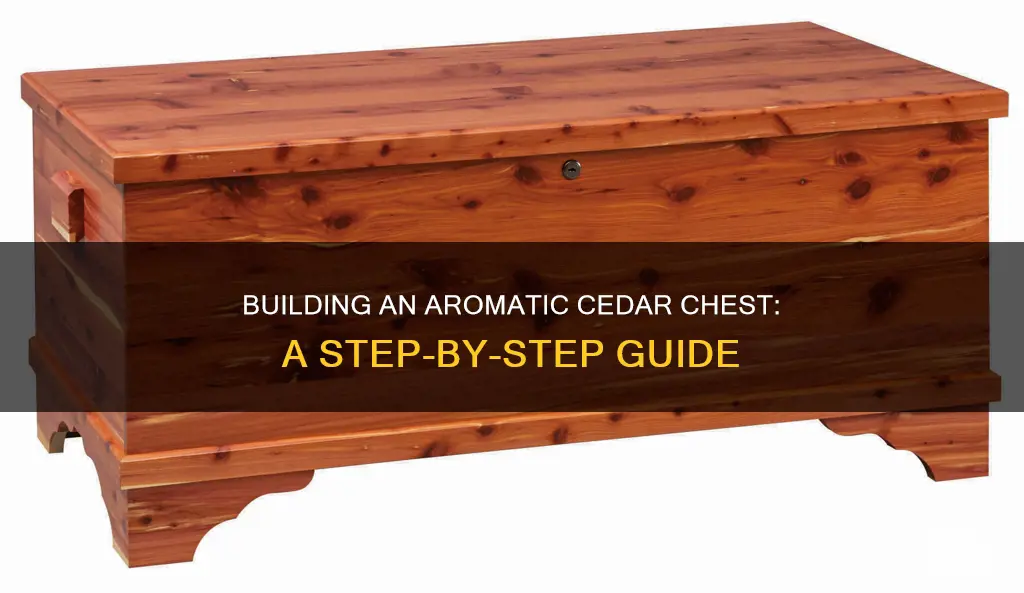

Aromatic cedar chests are a traditional choice for storing blankets and heirlooms due to their pleasant smell and ability to repel moths and other insects. The following is a step-by-step guide on how to build an aromatic cedar chest.

First, select aromatic red cedar boards with a thickness of 1 inch. Cut off any imperfections, such as knots or cracks, before gluing three pieces together to form a panel. Plane and sand the panels to a thickness of 3/4 inch. Assemble the box by joining the front, back, and side panels with data joints. Add the top and bottom panels, and mount the bottom to the box with nails. Attach the lid backs to keep the lid flat. Cut and assemble the legs by joining two-inch-wide cedar pieces with 45-degree angle cuts. Secure the legs to the bottom of the chest with screws. Sand the chest and finish it with a conversion varnish. Finally, attach the hardware, such as hinges and lid supporters, to complete your aromatic cedar chest.

| Characteristics | Values |

|---|---|

| Type of wood | Aromatic Cedar |

| Dimensions | 36" L x 17.5" W x 18.5" H |

| Weight | 40 lbs |

| Capacity | 5.1 cu ft |

| Shipping | Ground |

| Assembly | Fully assembled |

What You'll Learn

Choosing the right type of cedar wood

When it comes to choosing the right type of cedar wood for your aromatic cedar chest, there are a few options to consider. Cedar wood is a popular softwood that is known for its beautiful appearance, pleasant aroma, and durability. Here are some factors to keep in mind when selecting the type of cedar wood for your project:

True Cedars vs. False Cedars:

Firstly, it's important to distinguish between true cedars and false cedars. True cedars belong to the Cedrus genus in the Pinaceae family, while false cedars are species that have similar appearances or properties but are not in the same genus. Here are some common types of true cedars:

- Atlas Cedar (Cedrus atlantica): Native to Morocco and Algeria, with a light reddish-brown heartwood and good durability.

- Cyprian Cedar (Cedrus brevifolia): Similar to Cedrus libani, with light reddish-brown heartwood and easy workability.

- Deodar Cedar (Cedrus deodara): Native to the Himalayan region, known for its gigantic size, fragrant wood, and cultural significance.

- Cedar of Lebanon (Cedrus libani): Found in Mediterranean regions, with light reddish-brown heartwood and excellent durability.

Regional Availability:

The availability of certain types of cedar wood may depend on your region. For example, true cedars are more commonly found in the Himalayan and Mediterranean regions, while false cedars are prevalent in North America. Consider the following options based on regional availability:

- Alaskan Yellow Cedar (Cupressus nootkatensis): Native to the northwest coast of North America, with light-colored heartwood that darkens with age and natural durability.

- Bermuda Cedar (Juniperus bermudiana): Native to Bermuda, with aromatic reddish-brown wood traditionally used in shipbuilding and furniture making.

- Eastern Red Cedar (Juniperus virginiana): Abundant in Eastern North America, known for its reddish or violet-brown heartwood, decay resistance, and distinct cedar scent.

- Incense Cedar (Calocedrus decurrens): Native to Western North America, with light to medium reddish-brown heartwood and a unique spicy odor often used for pencils and outdoor furniture.

- Northern White Cedar (Thuja occidentalis): Found in Northeastern North America, with light reddish-brown heartwood, resistance to decay, and workability.

Project Specifics:

Consider the specific requirements of your cedar chest project. Different types of cedar wood may be more suitable for certain applications due to their aesthetic qualities, workability, or durability. Here are some factors to keep in mind:

- Aromatic Quality: If a strong cedar aroma is important for your chest, consider options like Eastern Red Cedar or Spanish Cedar, which are known for their distinct scents.

- Workability: Some types of cedar wood are easier to work with than others. For example, Cyprian Cedar and Cedar of Lebanon are known for their straight grain and easy workability.

- Durability: If your cedar chest will be subjected to varying environmental conditions, consider more durable options like Atlas Cedar or Cedar of Lebanon, which have excellent durability and insect resistance.

- Appearance: The visual appeal of the wood is also an important factor. Deodar Cedar, for instance, is known for its elegant appearance, making it a popular choice for ornamental woodworking.

Remember to take into account the availability, cost, and sustainability of the cedar wood you choose. With these factors in mind, you can select the right type of cedar wood for your aromatic cedar chest, ensuring a beautiful and functional end product.

Bottling IPA Early: Preserving Hop Aroma?

You may want to see also

Removing imperfections

Before gluing the pieces of wood together, it is important to cut off any imperfections like white edges, knots, cracks, or large white sections. This is done while the wood still has extra thickness to spare.

Filler

If there are any remaining imperfections, wood filler can be used to repair scratches, chips, gouges, and other surface imperfections. It is important to note that wood filler is intended for superficial issues and is not a substitute for a proper repair. There are a few different kinds of wood fillers, including stainable wood fillers, water-based wood fillers, and heavy-duty solvent-based wood fillers. Stainable wood fillers are receptive to staining, while water-based wood fillers are specially formulated for indoor use and can be stained or painted. Solvent-based wood fillers, on the other hand, are meant primarily for outdoor use and are commonly used on exterior siding and trim.

When using wood filler, start by sanding and cleaning the wood surface to remove any loose chunks of wood or flaking paint. Then, apply a preconditioner to the damaged area to prevent colour discoloration. Next, use a putty knife to apply the wood filler, overfilling slightly to account for shrinkage as it dries. Allow the filler to dry completely, then sand the area so that it is flush with the surrounding wood. Finally, apply your choice of finish to complete the repair.

Aroma 360: Easy Cleaning and Maintenance Tips

You may want to see also

Gluing panels together

To glue the panels together for your aromatic cedar chest, you will need to glue the edges of three pieces of stripped cedar. Use a glue that is known to work well with cedar, such as Elmers yellow carpenters glue or Titebond III. After applying the glue, clamp the pieces together to allow the glue to dry. You should give the glue at least 30 minutes to seal properly. You will need to repeat this process to create six panels in total, one each for the top, the bottom, the front, the back, and the sides.

Aromatic Full-Body Massage: Benefits and Techniques

You may want to see also

Sanding and finishing the panels

Once you have your panels glued together, it's time to plane and sand them. This process will ensure your cedar chest has a smooth, finished look and feel. Here are the steps to follow:

- Plane the panels: Use a planer to reduce the thickness of your panels to just over 3/4 inch. First, plane one side, then flip it over and plane the other side. Repeat this process until you achieve the desired thickness.

- Examine the panels: Carefully inspect the panels for any glue joints that are not completely smooth. If necessary, plane that side again to ensure a consistent finish.

- Sand the panels: Use a wide belt sander to sand the panels. Sand each side twice to achieve an even finish. The final thickness of your panels should be exactly 3/4 inch.

- Assemble the box: After your panels are planed and sanded, you can begin assembling the box. Join the front, back, and side pieces together using data joints and secure them with glue and nails. Clamp the assembled box for about 30 minutes to allow the glue to dry.

- Add the top and bottom: Shape the top and bottom panels using a shaper to create a profile on the front and sides. These panels should be identical. Mount the bottom panel to the box with nails, and then attach the top panel.

- Sand the assembled box: Use a polish sander with 120-grit sandpaper to sand all sides and the top of the assembled box. Follow up with 150-grit sandpaper for a smooth finish. Inspect the box carefully to ensure there are no minor scratches or imperfections.

- Finish the chest: Spray the chest with a conversion varnish. Allow the finish to dry, then sand it by hand. Apply a second coat of varnish for added protection and a smooth finish.

By following these steps, you will create a cedar chest with smooth, finished panels that showcase the natural beauty of the wood.

Enhancing Steak Flavor: Adding Aroma for an Unforgettable Experience

You may want to see also

Assembling the chest

Step 1: Prepare the Cedar Wood

Choose aromatic red cedar boards with a thickness of 1 inch. Cut and plane the boards to achieve a thickness of 3/4 inch for the front, back, sides, bottom, and top of the chest.

Step 2: Create the Panels

Examine the boards and cut off any imperfections, such as white edges, knots, cracks, or large white sections. Glue three pieces of cedar together for each panel, creating a total of six panels. Clamp the glued pieces together and let the glue dry for at least 30 minutes.

Step 3: Shape the Panels

Run the glued panels through a planer and a wide belt sander to achieve a consistent thickness of just over 3/4 inch. Examine the panels for any remaining glue joints and sand them down if necessary.

Step 4: Assemble the Box

Cut data joints at the end of the front and back panels. Fit the side pieces into these joints and secure them with glue and nails. Clamp the assembled box together for about 30 minutes to allow the glue to dry.

Step 5: Add the Top and Bottom

Run the top and bottom panels through a shaper to create a profile on the front and sides, making them identical. Mount the bottom panel to the box with nails, then attach the lid backs to the top panel to keep it flat.

Step 6: Attach the Legs

Cut eight two-inch-wide pieces of cedar to the desired length for the legs. Cut a profile on the edge of each piece and then cut a 45-degree angle on each end. Nail these pieces together to form the corners. Predrill screws into the bottom of the chest and attach the legs.

Step 7: Sanding and Finishing

Sand the entire chest with 120-grit sandpaper, then follow up with 150-grit sandpaper. Examine the chest for any minor scratches or imperfections and sand them down. Spray the chest with a conversion varnish and let it dry. Sand the chest by hand, then apply a second coat of varnish.

Step 8: Install Hardware

Predrill holes and attach the hinges and lid supporters to the chest. If desired, add a lock to the chest by predrilling holes and attaching the lock hardware.

Aromas vs Gas Masks: Do Scents Penetrate?

You may want to see also

Frequently asked questions

Aromatic red cedar is the recommended type of cedar wood to use when making a cedar chest.

Start with 1-inch-thick boards and work them down to 3/4-inch thickness during the cedar chest-making process. Remove any imperfections like white edges, knots, cracks, or large white sections.

First, glue three pieces of cedar wood together to form a panel. Plane and sand the panels, and then assemble the box by putting data joints at the end of each panel. Add the top and bottom of the chest, and then attach the legs.

Sand the chest with 120-grit sandpaper, and then follow up with 150-grit sandpaper. Spray the chest with a conversion varnish, and then sand it by hand. Apply a second coat of varnish.

Basic hardware includes hinges and lid supporters. You may also want to add a lock to your cedar chest.