Testing candles is an essential step before selling them to ensure customer satisfaction and safety. A candle burn test is conducted in a controlled environment to determine if a candle burns properly and safely from start to finish. It is recommended to initially test candles without any additives, such as fragrance oil or dye, to establish a baseline. This makes it easier to identify problems when testing different variables.

Each unique combination of wax, fragrance, wick, and container should be tested. The candle specifications, such as the type of wax, fragrance oil, wick, and container used, as well as temperatures and percentages of additives, are recorded. The candle burn test evaluates factors such as melt pool diameter, tunnelling, soot residue, flame size and movement, and fragrance throw.

It is crucial to test any new fragrance oil introduced to a candle recipe, as each fragrance oil behaves differently and can impact the candle's performance and safety. Therefore, it is recommended to test every new fragrance candle to ensure optimal performance and safety for your customers.

| Characteristics | Values |

|---|---|

| When to conduct a burn test | When creating a new candle recipe, adding dyes or micas, increasing or decreasing fragrance load, adding enhancers or wax additives, changing wax blends, using a new fragrance, or making candles in a new container shape or size |

| How to conduct a burn test | Trim the wick to 1/8"–3/16" (3.2mm–4.8mm), place candles on a heat-resistant surface in a safe, draft-free, undisturbed space with a moderate ambient temperature, light the candles and note the time, do not leave candles unattended, observe the melt pool after two hours, record details of the melt pool, flame height, and any smoking or sooting, extinguish the candle after four hours, let the candle cool completely and repeat the steps |

| What to look for during a candle burn test | A full melt in 2–3 hours, a 1/2" melt pool, and a 1/2" flame |

What You'll Learn

How to choose the right wick size

Choosing the right wick size for your candle is crucial to ensure optimal burning characteristics. Here are some detailed instructions to help you make the right choice:

Step 1: Understand the Basics

Start by familiarizing yourself with the different types of wicks available, such as zinc core wicks, ECO wicks, HTP wicks, and CD wicks. Each type has unique characteristics and is suitable for specific wax types and containers.

Step 2: Determine the Candle's Specifications

The specifications of your candle will play a significant role in wick selection. Consider the wax type, fragrance load, dye type, container diameter, and any additional additives used. All these factors will influence the performance of the wick.

Step 3: Consult Wick Charts

Wick manufacturers often provide wick charts with recommendations based on the candle's specifications. Use these charts as a starting point to narrow down your options. Keep in mind that these are just recommendations, and testing is still necessary to find the perfect wick.

Step 4: Sample Different Wick Sizes

Don't be afraid to experiment with different wick sizes. Test burn multiple wicks from the same brand, as well as different wick types, to find the optimal size for your candle. You can create sample candles with different wicks, all else being equal, and observe their performance.

Step 5: Observe Burning Characteristics

When testing the wicks, pay close attention to the burning characteristics. A properly wicked candle will have a steady flame with minimal flickering. The melt pool should extend to the edge of the container and be about 1/4" to 1/2" deep. The wick should burn cleanly with minimal to no carbon buildup.

Step 6: Evaluate and Adjust

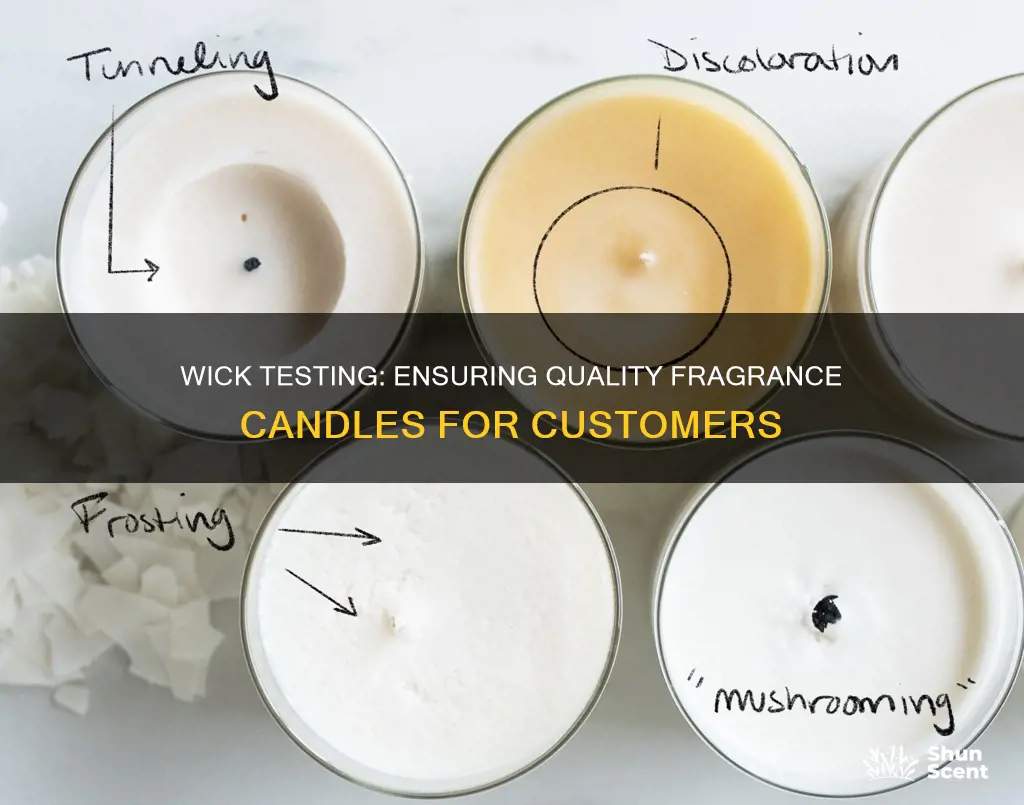

After each test burn, evaluate the performance of the wick. If the wick is too small (under-wicked), the candle will burn down the middle instead of reaching a full melt pool. If the wick is too large (over-wicked), the flame will be tall and flickery, with excessive carbon buildup and soot production. Adjust the wick size accordingly until you find the optimal size that burns cleanly and safely.

Step 7: Repeat Testing

Consistency is key. Repeat the testing process for each unique combination of wax, fragrance, wick, and container. Even small changes in these variables can impact the performance of the wick. Additionally, periodically test your candles to ensure that your chosen wick size remains optimal over time.

Step 8: Prioritize Safety

Always keep safety at the forefront. Avoid using wicks that produce excess smoke, soot, or mushrooming. Ensure the flame is steady and does not flicker excessively. Follow industry standards and guidelines for candle testing to create a safe product for your customers.

Choosing the right wick size may take some time and experimentation, but it is a crucial step in creating high-quality, safe, and enjoyable candles for your customers.

Creed Aventus: Where to Buy Your Next Signature Scent

You may want to see also

The importance of testing every unique fragrance oil

Testing every unique fragrance oil is a crucial step in candle-making. It ensures that your candles are safe to burn and perform optimally, with factors such as scent throw, flame size, and melt pool size all being dependent on the unique fragrance oil used.

Each fragrance oil behaves differently, and this can have a significant impact on the performance and safety of your candle. Some fragrance oils may burn too hot, clog the wick, or simply refuse to work with certain waxes or wicks. Therefore, it is essential to put each fragrance oil through a comprehensive testing process, even if the container and wax remain the same.

By testing every unique fragrance oil, you can identify any potential issues and make the necessary adjustments. For example, if a particular fragrance oil is causing excessive smoking or sooting, you may need to reduce the fragrance load or choose a different wick size. Additionally, certain fragrances may interfere with combustion, leading to excessive flame movement. Testing allows you to identify these issues early on and make the necessary changes to ensure a safe and enjoyable candle-burning experience for your customers.

Furthermore, testing helps you achieve a consistent burn and maximise scent throw. Each fragrance oil has its own unique characteristics, and these can affect how the wax melts and how the fragrance is released. By testing, you can fine-tune your candle recipe to ensure the fragrance is released effectively and the wax melts evenly.

In conclusion, testing every unique fragrance oil is a vital step in candle-making. It ensures the safety of your product, maximises its performance, and helps you deliver a consistent and enjoyable experience to your customers. While it may require time and effort, the benefits of thorough testing far outweigh the risks of taking shortcuts.

Aldi's US Fragrance Calendar: What's Available This Year?

You may want to see also

How to conduct a proper candle burn test

Conducting a candle burn test is essential to ensure your candles meet safety and performance standards. Here is a step-by-step guide on how to conduct a proper candle burn test:

Preparation:

Before conducting a burn test, ensure that your candles are properly cured. The curing process allows the wax to harden and stabilise, which can impact the burn test results. The curing time varies depending on the type of wax used:

- Vegetable wax: 14 days

- Paraffin wax: 24–48 hours

- Blends: 1–14 days

If you intend to test multiple candles, ensure they are clearly labelled with batch numbers. Prepare the following materials:

- A lighter or matches

- A stopwatch or timer

- An exhaust fan (optional)

Testing Procedure:

- Place your candle(s) on a flat, heat-resistant surface, ensuring there are no flammable materials nearby.

- Trim the wick to approximately 1/4 inch in length.

- Light the candle(s) and start the timer.

- Observe the candle flame, wick, and melted wax for the next 4 hours. Take note of any irregularities, such as dripping or excessive smoking.

- After 2 hours, observe the melt pool. The melt pool should have reached the full diameter of the candle by this point.

- After 4 hours, make further observations. The candle is considered to have passed the burn test if it has burned evenly, and there is less than 1 cm of wax remaining.

- Extinguish the candle flame and allow it to cool for at least 5 hours.

- Repeat the above steps until the candle is completely burned or fails the test.

Evaluating the Results:

- Hot throw: Did the candle produce a strong fragrance while burning, and did it extend into the surrounding space?

- Wick condition: Check for carbon buildup on the wick, which may indicate an oversized wick.

- Discolouration: Evaluate the colour of the wax after cooling. Discolouration, especially severe discolouration, may be a sign of an oversized wick.

Customising the Test:

The standard burn test can be modified to suit your specific needs. For example, when testing a new fragrance, you may want to increase the burn time to understand how the scent develops over a longer period. Additionally, testing different wicks can help determine which one burns the candle most evenly.

Remember, conducting thorough burn tests is crucial to ensure the safety and performance of your candles.

Opium Fragrance Evolution: A Study of Changing Scents

You may want to see also

The different types of candle wicks available

The wick is an important part of a candle. It influences the diffusion of the scent, safety, and aesthetics. Different wicks are suited to different types of candles, and choosing the right wick is critical to making a candle that burns cleanly and properly. Here are some of the different types of candle wicks available:

- Cotton wicks: These are the most commonly used wicks for scented candles. They are natural, easy to light, durable, and can burn for hours. They are also known to be able to absorb the wax.

- Linen wicks: Linen wicks are similar to cotton wicks in terms of their ecological and sustainable nature, ease of use, and durability. However, linen wicks are more aesthetic and resistant to deformation, even with significant thermal shock.

- Silk wicks: Silk wicks are entirely natural, resistant, and durable. However, they are very expensive, likely due to the rarity of silk. Synthetic silk is available as a less expensive alternative, but it is not as environmentally friendly.

- Wooden wicks: Wooden wicks are a relatively new option that creates the atmosphere of a fireplace with a crackling sound. They are ecological and environmentally friendly. They are suitable for containers but not for pillars or votives.

- Synthetic fiber wicks: Synthetic wicks are the most economical option. They are resistant and can burn well even in humid conditions. However, they have undergone chemical treatments, which may make them harmful to health during combustion, and they are less environmentally friendly.

- Zinc core wicks: These wicks are widely used and help the wick remain straight during pouring and burning. They are recommended for votives, pillars, and small containers.

- CD series wicks: This type is a favourite among seasoned candlemakers. They are flat braided with a special paper filament woven around them, promoting a consistent burn and ensuring a wick-trimming flame posture. They are suitable for harder-to-melt viscous waxes, such as paraffin and vegetable base (soy).

- ECO series wicks: This series is specifically designed for natural waxes like soy and palm wax. They are flat, coreless cotton wicks braided with thin paper filaments that improve rigidity and reduce "afterglow" and smoke. They have been primed with vegetable wax, allowing candles to be marketed as all-natural.

- HTP series wicks: These are coreless, cotton braided wicks with paper filaments that bend at the tip, forcing the tip into the outermost portion of the flame for more complete combustion and less smoke. They are suitable for votives, pillars, containers, and gel candles.

- LX series wicks: Flat braided cotton wicks that are chemically treated to reduce "mushrooming," smoke, and soot. They are suitable for a wide range of applications and perform well with paraffin and IGI 6006.

- Flat wicks: Flat-plaited or knitted wicks, usually made from three bundles of fibre, that provide consistent burning and curl in the flame for a self-trimming effect. They are the most commonly used wicks and are often found in taper and pillar candles.

- Square wicks: Braided or knitted wicks that curl in the flame and are preferred for beeswax applications. They help inhibit wick clogging, which can occur with certain wax formulations, pigments, or fragrances.

- Specialty wicks: These wicks are designed for specific candle applications, such as oil lamps and insect-repelling candles.

Mixing Sage Essential Oils: Can You Add Fragrance?

You may want to see also

How to test for scent throw performance

Testing the scent throw performance of a candle is a crucial part of the candle-making process. While there is no perfect framework for measuring scent throw, there are several steps and best practices you can follow to ensure optimal results. Here is a guide on how to test for scent throw performance:

Step 1: Prepare the Candles for Testing

Start by choosing your container and wax blend. It is recommended to use consistent containers for your candles to avoid additional tests. Then, select the wick size you think you may need and choose the next sizes up and down to determine the optimal wick size. For example, if you think an ECO-8 wick is suitable, also test an ECO-6 and an ECO-10. Fill the containers halfway with wax, as this allows you to observe how the candle burns as the container insulates it further down. Allow the wax to cure for 1-2 days before lighting.

Step 2: Conduct the Wick Sizing Test

For accurate results, use a consistent container and sample 1-3 wicks from each brand you are testing. Burn the candles simultaneously, spacing them at least 3 inches apart on a level surface away from drafts and windows. Set a timer for approximately 1 hour of burn time for each 1 inch of diameter. Observe if the candles reach a full melt pool (melted edge to edge and ¼” deep) within the allotted time. The candles that achieve this will indicate the potential range of usable wick sizes for your vessel and wax type.

Step 3: Conduct a Burn Test with Fragrance

If possible, use the same batch of wax for all test candles to eliminate variation. Label your candles with the following information: wax type/blend ratio, percentage of fragrance used (typically tested at 6%), and any other relevant details. Allow the candles to cure for 3-5 days before the test burn. If testing multiple scents, spread them out in different spaces in your home. Light the test candles away from drafts and windows, ensuring they burn on a level heat-resistant surface. Set a timer for 1 hour per 1 inch of diameter.

Step 4: Evaluate the Results

There are several factors to consider when evaluating the performance of your test candles:

- Hot throw: Did the candle accurately capture the intended fragrance, and did the scent extend into the space? For an 8-ounce candle, expect to fill 8-10 square feet. For a 2-4 ounce candle, the fragrance should be noticeable within 2-3 feet. If the fragrance intensity is weak, consider retesting with a higher fragrance percentage or a different wick size.

- Wick condition: Examine the wick after burning. If you observe carbon buildup that resembles rounded mushroom tops, this indicates an oversized wick, and you should test a smaller size. Excessive carbon buildup can lead to safety issues as the candle may burn too quickly and get too hot.

- Discoloration: After the test burn, allow the candle to cool and check for discoloration where the melt pool was. Significant discoloration could be a sign that the wick is too large, causing the melt pool to overheat.

- Fragrance compatibility: Once you've found the optimal wick size for your wax blend and container, test each fragrance you plan to use. Fragrance oil can alter the viscosity of the candle, so a wick size that worked without fragrance may not work as well with fragrance added. Test at the lower end of the usage rate to conserve fragrance, and if done properly, a good hot throw should be achieved at 6-8%.

Step 5: Refine and Re-test

The process of testing and refining is iterative. Re-test your candles with different variables, such as fragrance load and wick size, to optimize their performance. Additionally, re-test new lots of wax to ensure consistency and quality control. Remember that each fragrance oil behaves differently, so test each unique fragrance oil for safety and performance, even if the container and wax remain the same.

Gucci Guilty: Summer Scent or Not?

You may want to see also

Frequently asked questions

Testing candles ensures they burn correctly, safely, and smell great. Testing is necessary to keep your business reputable and out of the headlines.

First, make and cure your candles. Then, burn the candle in a controlled environment for up to 4 hours. Record all vital details about the candle recipe for future reference.

Observe the flame size and movement, melt pool size, soot, and the temperature of the container. These factors will indicate whether your candle is working well or if adjustments are needed.

Wick testing involves testing different wick sizes and types to determine the best combination for your candle recipe. Create candles with different wicks, burn them next to each other, and observe which wick burns the best.